-

Top 5 Common Problems with Dust Control Systems and How to Fix Them

Dust control systems are integral to maintaining clean air and preventing pollution in various industrial sectors. A well-designed dust control system is essential for minimizing h...

-

Bag Filters vs. Cartridge Filters: Which is Better for Your System?

Introduction In industries where air pollution control and waste gas treatment are crucial, selecting the right type of dust filter is essential for both operational efficiency and...

-

The Role of Bag Filters in Preventing Air Pollution: Key Benefits and Applications

Introduction Air pollution remains a significant global concern, especially in industrial environments where the emissions of particulate matter, harmful gases, and toxins are freq...

-

A Step-by-Step Guide to Maintaining Your Electrostatic Precipitator

An electrostatic precipitator (ESP) is a crucial component in industrial processes that need to control particulate pollution, particularly in power plants, cement factories, and o...

WESP Wet Electrostatic Precipitator Filter Manufacturers

The wet electrostatic precipitator has the same dust removal principle as the electrostatic precipitator. Both charge the dust, and the charged dust moves to the collecting electrode under the action of the electric field force to achieve the effect of gas-solid separation. As for the particles attached to the collecting electrode, the electrostatic precipitator uses vibration and ultrasonic waves to make the dust fall into the ash bin at the bottom, while the wet electrostatic precipitator uses regular flushing to remove the dust attached to the collecting electrode as the flushing liquid flows.

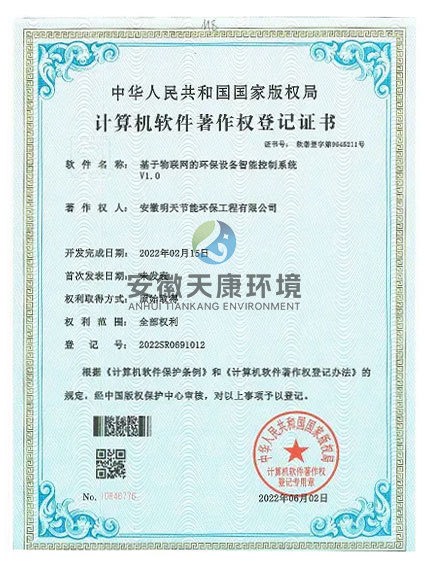

Anhui Tiankang Environmental Technology Co., Ltd. (formerly Wuxi Mingtian Environmental Protection Equipment Co., Ltd.) was established in 2002. It is a private high-tech enterprise dedicated to environmental protection and governance. The company is mainly engaged in environmental engineering design, environmental protection facility operation and environmental pollution control technology research and development, and undertakes various dust removal systems, flue gas desulfurization and denitrification systems and VOC systems and other engineering general contracting business. We are WESP Wet Electrostatic Precipitator Filter Solution Provider and China WESP Wet Electrostatic Precipitator Filter Manufacturers, At present, the company's products include various bag dust collector systems (including raw materials, batching, pelletizing, sintering, ironmaking, steelmaking, rolling and other aspects of steel mills; foundry industry, pharmaceutical industry, glass industry, cement industry, non-ferrous metal smelting industry, etc.), converter primary dust removal flue gas recovery system, slag treatment system, VOC treatment system (including activated carbon adsorption device, catalytic combustion device, RTO and UV pretreatment + zeolite wheel adsorption + RCO device, etc.), as well as flue gas heat exchanger, cooler, capture hood (including electric furnace fully enclosed hood, roof hood, converter front and rear hood, blast furnace tapping port, slag skimmer hood, various belt hoods, and various scattered point hoods in steelmaking workshop, etc.), mobile ventilation slots, mufflers, desulfurization towers, ash conveying equipment, ventilation duct flexible compensators, pipeline sliding supports, condensate drainers, bags, keels and other customized accessories.

Tiankang Environment has two branches. One is Wuxi Mingtian Environmental Protection Equipment Co., Ltd., which is located in Wuxi, a famous city in the south of the Yangtze River with a developed economy and picturesque scenery. It has convenient transportation and rich natural and cultural landscapes. The other is Anhui Tiankang Environmental Technology Co., Ltd. (formerly Anhui Mingtian Energy Saving and Environmental Protection Engineering Co., Ltd.), which is located in Lu'an, an old revolutionary base with a long history, mountains and water, and a pleasant climate. The company sincerely welcomes friends from all walks of life to visit and guide with an open attitude. It is willing to provide technical services for all walks of life and provide a stage for people with lofty ideals to display their wisdom and talents.

The company focuses on the future, is determined to protect the environment, and regards returning a fresh, blue and clear sky to mankind as the company's goal!

What Are the Key Benefits of Using a WESP Wet Electrostatic Precipitator Filter?

The WESP wet electrostatic precipitator filter has emerged as one of the most advanced and reliable technologies for industrial air pollution control, particularly in industries with complex emission profiles. Unlike conventional dry electrostatic precipitators (ESPs) or fabric filters, the WESP system combines electrostatic precipitation with a liquid flushing mechanism, making it highly effective for capturing fine particulate matter, acid mists, heavy metals, and other challenging pollutants.

Industries such as steel manufacturing, chemical processing, power generation, and non-ferrous metal smelting face increasingly stringent environmental regulations. These sectors require emission control systems that can handle high moisture, corrosive gases, and sticky particulate matter without frequent maintenance or performance degradation. The WESP wet electrostatic precipitator filter is uniquely suited for these applications due to its ability to continuously clean electrodes with water, preventing buildup and ensuring consistent efficiency.

Furthermore, as global environmental standards evolve—such as China’s Ultra-Low Emission (ULE) policies and the U.S. EPA’s MATS (Mercury and Air Toxics Standards)—industries must adopt technologies that not only meet current limits but also future-proof their operations. The WESP wet electrostatic precipitator filter is increasingly integrated into multi-pollutant control systems, working alongside scrubbers, selective catalytic reduction (SCR) units, and VOC abatement technologies to deliver comprehensive air quality solutions.

1. Superior Particle Removal Efficiency

One of the most significant advantages of the WESP wet electrostatic precipitator filter is its exceptional ability to capture fine and submicron particulate matter. Traditional dry ESPs and bag filters struggle with particles below 2.5 microns (PM2.5), often allowing a significant portion to escape into the atmosphere. In contrast, WESP systems achieve removal efficiencies exceeding 99% for particles as small as 0.1 microns, making them ideal for industries where ultrafine dust, acid aerosols, or heavy metal emissions are a concern.

The enhanced efficiency of WESP technology stems from its unique operating principle. Like dry ESPs, the WESP wet electrostatic precipitator filter charges incoming particles using a high-voltage electric field. However, instead of relying on mechanical rapping to dislodge collected dust (which can cause re-entrainment), it uses a controlled water-wash system to flush captured particles from the collection plates. This continuous cleaning mechanism prevents particle buildup, ensuring sustained high performance without efficiency drops over time.

Industries such as cement production, where kiln exhaust contains high concentrations of fine alkaline dust, benefit greatly from WESP systems. Similarly, in semiconductor manufacturing or pharmaceutical production, where process emissions may include hazardous submicron particles, the WESP wet electrostatic precipitator filter provides a critical layer of protection for both environmental compliance and worker safety.

2. Effective Handling of Challenging Emissions

Many industrial processes generate emissions that are inherently difficult to treat—whether due to high moisture content, corrosive gases, or sticky particulate matter. Dry ESPs often fail in these environments because dust accumulation on electrodes leads to arcing, reduced efficiency, and frequent maintenance. Fabric filters, meanwhile, are prone to blinding when exposed to hygroscopic or adhesive dust.

The WESP wet electrostatic precipitator filter overcomes these challenges by using water to continuously clean the collection surfaces. This feature is particularly valuable in industries such as:

- Steelmaking: Converter and electric arc furnace emissions contain sticky iron oxide particles, heavy metals, and SO₂. WESP systems prevent clogging and corrosion, ensuring stable operation.

- Waste Incineration: Flue gases from waste-to-energy plants carry HCl, dioxins, and fly ash with high moisture content. WESP technology effectively captures these pollutants while resisting acid corrosion.

- Chemical Processing: Acid mist (e.g., sulfuric or phosphoric acid) is a major byproduct in fertilizer production. WESP systems neutralize and remove these aerosols efficiently.

Additionally, the WESP wet electrostatic precipitator filter can be constructed from corrosion-resistant materials such as fiberglass-reinforced plastic (FRP), stainless steel, or conductive polymers, further enhancing its durability in aggressive environments.

3. Reduced Maintenance and Operational Costs

A major drawback of dry ESPs is their reliance on mechanical rapping systems, which require regular maintenance and can lead to electrode misalignment or damage over time. Baghouses, while effective for certain applications, need frequent filter replacements and compressed air for cleaning, driving up operational expenses.

The WESP wet electrostatic precipitator filter significantly reduces these costs by eliminating moving parts in the collection zone. Instead of mechanical rapping, it uses automated water sprays to clean electrodes, minimizing wear and tear. Key cost-saving benefits include:

- Lower energy consumption (no need for pulse-jet cleaning like in bag filters).

- Reduced downtime (continuous washing prevents performance degradation).

- Longer equipment lifespan (corrosion-resistant materials and no abrasive rapping).

For industries operating around the clock, such as power plants or large-scale metallurgical facilities, the reduced maintenance requirements of WESP systems translate into higher productivity and lower total cost of ownership.

4. Compliance with Stringent Environmental Regulations

Governments worldwide are imposing stricter limits on particulate emissions, acid gases, and heavy metals. The WESP wet electrostatic precipitator filter is designed to meet and exceed these standards, making it a preferred choice for industries facing regulatory scrutiny.

For example:

- China’s Ultra-Low Emission (ULE) standards require steel plants to achieve particulate emissions below 10 mg/m³. WESP systems consistently meet this threshold.

- The U.S. EPA’s MATS rule targets mercury and acid gas emissions from coal-fired boilers. WESP technology effectively captures these pollutants when combined with wet scrubbing.

- EU Industrial Emissions Directive (IED) mandates best available techniques (BAT) for waste incinerators, where WESP is often specified.

Because the WESP wet electrostatic precipitator filter can be integrated with other pollution control systems (e.g., scrubbers for SO₂ removal or activated carbon injection for mercury control), it provides a versatile solution for multi-pollutant compliance.

5. Adaptability to High-Temperature and High-Humidity Streams

Many air pollution control technologies struggle with saturated gas streams or high-temperature flue gases. Bag filters, for instance, cannot handle moist exhaust without risking filter blinding, while dry ESPs may experience increased resistivity issues in humid conditions.

The WESP wet electrostatic precipitator filter, however, thrives in these environments. Its water-wash mechanism ensures that even sticky or moisture-laden particles are effectively captured. Industries that benefit from this capability include:

- Glass Manufacturing: Furnace exhaust contains sodium sulfate aerosols and high heat.

- Non-Ferrous Smelting: Flue gases are often humid and carry metal fumes (e.g., lead, arsenic).

- Biomass Power Plants: Combustion gases have high moisture and alkali content.

By maintaining efficiency under these challenging conditions, WESP systems offer unparalleled reliability compared to alternative technologies.

6. Synergy with Other Pollution Control Technologies

Modern industrial facilities rarely emit just one type of pollutant. Most flue gases contain particulate matter, acid gases (SO₂, HCl), NOx, and volatile organic compounds (VOCs). The WESP wet electrostatic precipitator filter is frequently deployed as part of an integrated system, working alongside:

- Wet Scrubbers (for SO₂/acid gas removal)

- Selective Catalytic Reduction (SCR) (for NOx reduction)

- Activated Carbon Adsorbers or RTOs (for VOC abatement)

This modularity allows engineers to design customized solutions that address multiple pollutants in a single streamlined process. For example, in a waste incineration plant, the flue gas might first pass through a scrubber for acid removal, then a WESP for fine particulate and heavy metal capture, followed by an SCR unit for NOx control.

The WESP wet electrostatic precipitator filter represents a significant advancement in industrial air pollution control, offering superior efficiency, lower operating costs, and unmatched adaptability to challenging emissions. As environmental regulations tighten worldwide, industries must adopt technologies that not only meet current standards but also provide flexibility for future compliance needs.

With its ability to handle high humidity, corrosive gases, and fine particulate matter—while integrating seamlessly with other pollution control systems—the WESP wet electrostatic precipitator filter is poised to remain a cornerstone of sustainable industrial operations for years to come.

English

English Français

Français عربى

عربى 简体中文

简体中文