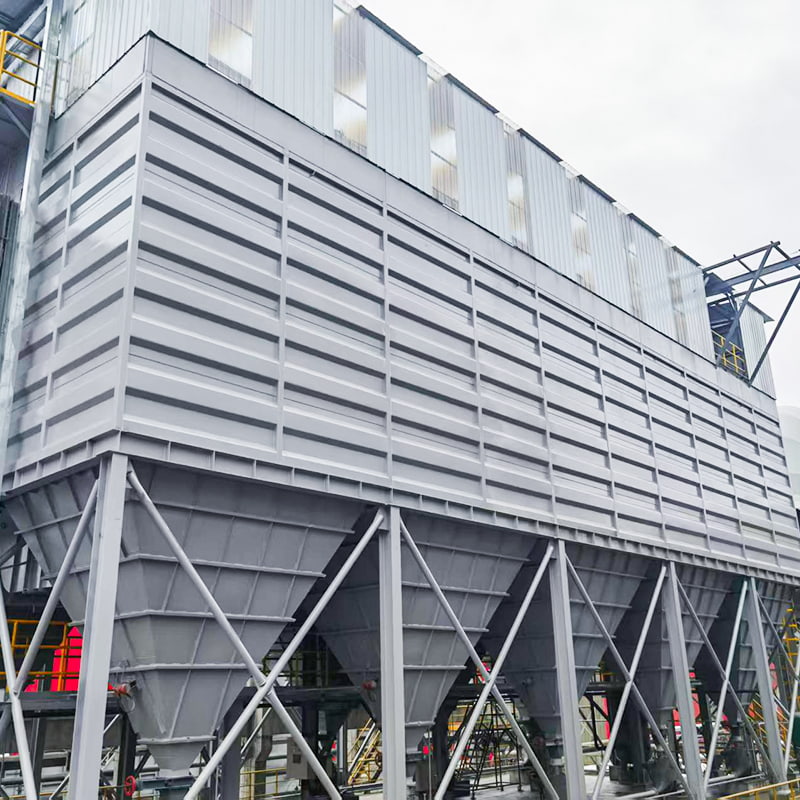

Low-Pressure Pulse Jet Filter Cartridge Dust Collector

CONTACT US-

Top 5 Common Problems with Dust Control Systems and How to Fix Them

Dust control systems are integral to maintaining clean air and preventing pollution in various industrial sectors. A well-designed dust control system is essential for minimizing hazardous airborne particles, ensuring compliance with environmental regulations, and improving workp...

-

Bag Filters vs. Cartridge Filters: Which is Better for Your System?

Introduction In industries where air pollution control and waste gas treatment are crucial, selecting the right type of dust filter is essential for both operational efficiency and environmental responsibility. Among the various filtration systems, bag filters and cartridge filte...

-

The Role of Bag Filters in Preventing Air Pollution: Key Benefits and Applications

Introduction Air pollution remains a significant global concern, especially in industrial environments where the emissions of particulate matter, harmful gases, and toxins are frequent. Effective air pollution control systems are crucial to ensuring that industries comply with en...

Is the Baghouse Dust Collector Obsolete? Is the Low-Pressure Pulse Jet Filter Cartridge Dust Collector the Future?

In the vast landscape of industrial flue gas treatment, dust collection technology is in a constant state of evolution. From the early mechanical shaking systems to the widely used baghouse filters of today, each technological leap has aimed to provide more efficient and stable solutions. However, with increasingly strict environmental standards and the push for more refined industrial processes, traditional baghouse dust collectors are beginning to show their limitations. In this context, a new dust collection technology is quietly emerging, capturing attention with its unique advantages: the LOW-PRESSURE PULSE JET FILTER CARTRIDGE DUST COLLECTOR. So, does the advent of this new technology mean that traditional baghouse filters are a thing of the past? Can the filter cartridge dust collector truly dominate the future? To answer these questions, we must conduct a deep analysis of its working principles, core advantages, and the challenges it faces.

The Core Principle of Filter Cartridge Dust Collectors: Achieving Precise Filtration with a Small Footprint

The heart of the filter cartridge dust collector lies in its filtration element: the filter cartridge. Compared to traditional filter bags, the filter cartridge is a more ingenious design. It is typically made of a multi-layered pleated fibrous material, which allows a single cartridge to have a much larger filtration area than a single filter bag of the same size. This “small footprint, big impact” design is the key to why filter cartridge dust collectors can significantly reduce the equipment’s physical footprint and engineering costs.

When dust-laden flue gas enters the dust collector, it passes over the outer surface of the filter cartridges. Driven by the airflow, dust particles are trapped on the outer surface of the cartridge, while the clean gas passes through the inside and is discharged, achieving solid-gas separation. As operation time increases, the dust accumulated on the outer surface of the cartridge forms a filter cake. This layer of dust, to some extent, improves filtration efficiency. However, when the dust layer reaches a certain thickness, the equipment’s operational resistance also increases, impeding normal airflow.

To solve this problem, filter cartridge dust collectors use a low-pressure pulse jet cleaning method. When the equipment’s resistance reaches a preset value, the system automatically activates a pulse valve, spraying a powerful, low-pressure burst of compressed air into the inside of the cartridge. This airflow instantly impacts the cartridge, causing it to vibrate slightly and dislodge the dust attached to its outer surface into the hopper below. This precise and efficient cleaning method quickly restores the filter cartridge’s filtration capacity, ensuring stable equipment operation.

It’s worth noting that due to the dense pleated structure of the filter cartridges, there are strict requirements for the filtration velocity. To protect the integrity of the cartridge and ensure stable filtration, the filtration velocity generally needs to be kept below 0.8m/min. This is a significant characteristic compared to other types of dust collectors and is crucial for achieving precise filtration, ensuring that the flue gas emission concentration is less than 8mg/Nm³.

A Double-Edged Sword: The Advantages and Limitations of Filter Cartridge Dust Collectors

The advantages of a low-pressure pulse jet filter cartridge dust collector are clear. First, its extremely high filtration efficiency allows it to easily meet the most stringent current environmental emission standards, which is vital for companies pursuing ultra-low emissions. Second, its small footprint and lower engineering costs make it particularly appealing in situations with limited space or tight project budgets. Additionally, because the filter cartridges have a more robust structure, they are easier to replace and maintain than traditional filter bags, reducing the time workers are exposed to dusty environments.

However, no technology is perfect, and filter cartridge dust collectors have their own limitations. The most significant restriction is the requirement for the properties of the dust being collected. The filter cartridges require the dust to be fluid and non-caking, capable of being easily dislodged by the pulse jet airflow. If the dust is hygroscopic or prone to caking, such as certain chemical raw materials or cement dust in humid environments, a hard filter cake can form on the surface of the cartridge. The pulse jet cleaning will be unable to remove it effectively, leading to cartridge failure.

Furthermore, the equipment has clear limitations regarding flue gas conditions. Due to the current limitations of filter cartridge materials, the operating temperature of a filter cartridge dust collector generally does not exceed 150°C. While cartridges for higher operating temperatures are still under development, at this stage, they are not suitable for all high-temperature applications. More importantly, for flue gas where the moisture content exceeds a 10% volume ratio, filter cartridge dust collectors are also unsuitable. Excessive humidity can cause the dust to deliquesce and stick to the cartridge surface, leading to its failure. Similarly, gases containing significant corrosive or acidic substances are currently not suitable for filter cartridge dust removal.

To handle large volumes of flue gas, these dust collectors are often designed with a compartmentalized structure. When one compartment is undergoing cleaning, the others can continue to operate, ensuring the continuous operation of the entire system. This modular design also facilitates convenient maintenance and inspection.

Applicable Scenarios and Best Practices: Who Benefits Most from Filter Cartridge Dust Collectors?

Based on the advantages and limitations mentioned above, the ideal application scenarios and target users for a low-pressure pulse jet filter cartridge dust collector become clear. It is particularly well-suited for industrial sectors that require precise filtration and where the flue gas conditions are relatively mild.

- Steel Mills: In certain processes like grinding and polishing, the generated dust has a small particle size, and the flue gas temperature is moderate, making it an excellent fit for a filter cartridge dust collector for efficient capture.

- Power Industry: In the coal conveying systems and crushing workshops of coal-fired power plants, the generated coal dust is dry and easy to clean. Filter cartridge dust collectors can provide a stable and reliable dust removal effect. Anhui Tiankang Environmental Technology Co., Ltd specializes in delivering high-performance filtration solutions for these exact scenarios, offering customized designs that optimize dust removal efficiency and system longevity.

- Cement Plants: In processes like raw material drying and packaging, the generated dust is dry and highly fluid. A filter cartridge dust collector can also handle these conditions effectively.

- Food Processing Plants: During grain processing and flour production, the generated dust requires high-efficiency filtration to ensure product quality and environmental hygiene. Filter cartridge dust collectors can achieve ultra-low emissions, meeting stringent sanitation standards.

In addition, this product can be customized according to customer requirements. Whether it’s adjusting the gas volume, equipment size, or an optimized design for a specific type of dust, a customized service can be provided to achieve the best possible dust removal effect.

Conclusion: Technological Innovation, Not Complete Replacement

In conclusion, the low-pressure pulse jet filter cartridge dust collector, as an emerging dust removal technology, has brought new vitality to the industrial dust control sector with its high efficiency, small footprint, and low cost. In many specific operating conditions, it indeed holds an advantage over traditional baghouse dust collectors, achieving higher filtration efficiency and lower emission concentrations.

However, we cannot therefore conclude that traditional baghouse dust collectors are obsolete. The filter cartridge dust collector has strict limitations on dust properties, flue gas humidity, and temperature, which means it cannot replace the application of baghouse filters in all conditions. For instance, when dealing with high-humidity, high-temperature, or sticky dust, a baghouse filter remains a more reliable choice.

Therefore, a more accurate conclusion is that the low-pressure pulse jet filter cartridge dust collector is a technological innovation that expands the boundaries of dust control, but it is not a complete replacement for traditional technology. In practical applications, businesses should select the most suitable dust control technology by comprehensively considering factors such as dust properties, flue gas parameters, investment costs, and maintenance convenience. This is the true path to achieving efficient, stable, and economical flue gas treatment.

English

English Français

Français عربى

عربى 简体中文

简体中文