How Do Dust Collectors Help in Reducing Air Pollution in Industrial Environments?

By Admin

By Admin

Introduction

Industrial environments, especially in sectors like steel manufacturing, waste gas treatment, and chemical processing, are significant contributors to air pollution. The release of dust, gases, and particulate matter into the atmosphere not only harms the environment but also poses serious health risks to workers and nearby communities. Dust collectors are essential tools that help mitigate this problem. These systems are designed to capture and remove harmful dust particles and exhaust gases, making industrial operations more environmentally friendly and compliant with air pollution regulations.

What is a Dust Collector?

A dust collector is an air quality improvement system used in industrial applications to remove particulate matter from the air. These systems can be applied in various industries, including steel production, cement manufacturing, and chemical processing. Dust collectors are typically used to capture airborne dust and particulate matter generated during manufacturing processes like grinding, cutting, welding, and other activities that cause dust emissions.

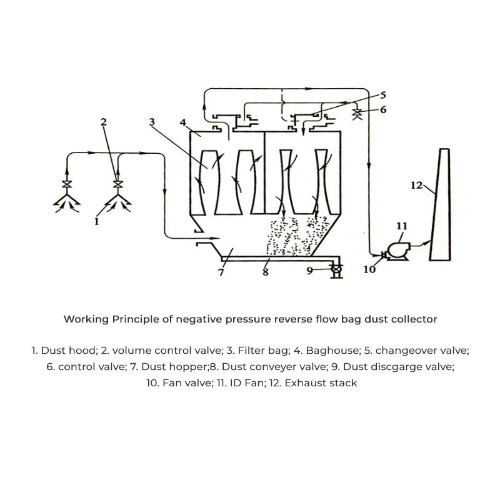

There are different types of dust collectors, including baghouses, cyclone separators, electrostatic precipitators, and wet scrubbers. Each type has its own advantages depending on the specific industrial requirements and the nature of the pollutants involved.

The Role of Dust Collectors in Air Pollution Control

Dust collectors play a pivotal role in air pollution control, ensuring that industrial operations are cleaner and safer. Their primary function is to capture dust particles, smoke, and other particulates from exhaust gases before they can be released into the atmosphere.

By improving air quality and reducing the environmental impact of industrial activities, dust collectors help industries meet stringent environmental standards and regulations. This is particularly crucial for industries like steel plants, where large amounts of particulate matter and harmful gases are generated during the production process.

Key Functions of Dust Collectors:

Dust Collection: Dust collectors effectively remove solid particles, such as metal dust, ash, and fine particulate matter, from industrial air streams. This is vital for ensuring cleaner air in the workplace and for preventing environmental contamination.

Exhaust Gas Purification: In industries like steel plants and chemical processing, exhaust gases generated during operations can contain harmful pollutants, including carbon monoxide, sulfur dioxide, and volatile organic compounds (VOCs). Dust collectors equipped with filtration technologies help purify these gases, reducing their harmful effects.

Waste Gas Treatment: Waste gas treatment systems work hand-in-hand with dust collectors to treat and neutralize harmful emissions. By capturing the particulate matter, these systems ensure that gases are filtered and treated before they are released into the environment.

Compliance with Regulations: Governments and regulatory bodies have set strict standards for air quality in industrial zones. Dust collectors help industries stay compliant with these regulations by reducing the amount of airborne pollutants that are discharged.

Applications of Dust Collectors in Industrial Environments

Dust collectors are used across various industries, each with unique applications and needs for dust removal. Let’s look at some key industries where dust collectors are essential for reducing air pollution.

Steel Plants

Steel plants are major sources of dust and particulate emissions. During processes like smelting, casting, and refining, vast amounts of particulate matter are generated. Steel plants rely heavily on dust collectors to capture these emissions and prevent their release into the atmosphere.

In particular, dust collectors are crucial in handling converter and oxygen converter gases. These gases typically contain large amounts of harmful gases and particulate matter, which need to be filtered out to maintain air quality. Dust collection systems in steel plants help ensure the proper treatment of exhaust gases, improving air quality both within the plant and in surrounding areas.

Key Dust Collection Systems in Steel Plants

| Dust Collector Type | Primary Function | Applications in Steel Plants |

|---|---|---|

| Baghouse Dust Collector | Captures fine particulate matter from exhaust gases | Used in converter gas collection and purification |

| Cyclone Dust Collector | Separates dust by centrifugal force | Employed for large particulate removal in steel mills |

| Electrostatic Precipitator | Removes fine dust particles by applying electric fields | Ideal for gas treatment in oxygen converter systems |

| Wet Scrubber | Filters out pollutants using water | Used for cleaning exhaust gases in steel production |

Converter/Oxygen Converter Systems

In steel production, the converter process involves the refining of molten iron into steel, which generates large quantities of exhaust gases and particulates. Dust collectors are integrated into converter systems to capture flue gas and particulate matter. The recovered gases can be treated further for use in energy recovery systems, reducing environmental impact.

Dust collectors in these applications are often designed to handle high temperatures and abrasive materials, ensuring long-term reliability and efficiency.

Waste Gas Treatment in Chemical Manufacturing

Chemical manufacturing plants often produce hazardous gases and particulates that need to be filtered and neutralized. Dust collectors in these environments help reduce airborne contaminants, ensuring that the air quality is maintained within acceptable levels.

These systems work alongside other air pollution control technologies like scrubbers and absorbers to provide a comprehensive solution for waste gas treatment.

How Dust Collectors Help in Exhaust Gas Purification

Exhaust gas purification is an essential part of industrial air pollution control. Dust collectors serve as the first line of defense in ensuring that exhaust gases are free of particulates before they are further treated for gas-phase pollutants.

By removing solid particles from the exhaust streams, dust collectors reduce the load on secondary treatment systems, such as scrubbers and catalytic converters. This not only improves the efficiency of the entire air pollution control system but also reduces maintenance costs and extends the life of the equipment.

Benefits of Dust Collectors in Reducing Air Pollution

Dust collectors provide several key benefits when it comes to air pollution reduction:

Improved Air Quality: By capturing dust and particulate matter, dust collectors help improve the quality of both indoor and outdoor air. This contributes to a safer work environment and reduces the health risks associated with air pollution.

Energy Efficiency: Many dust collection systems are designed to recover and reuse gases, making them energy-efficient. In industries like steel production, recovered gases can be used for heating or power generation, reducing the overall environmental footprint.

Compliance with Standards: Dust collectors help industries comply with air quality regulations by keeping particulate emissions within permissible limits. This is especially important for industries like steel manufacturing, where the amount of dust and exhaust gas generated can be substantial.

Cost-Effective Pollution Control: Investing in dust collectors and related air pollution control technologies can help reduce costs associated with environmental fines and penalties, as well as healthcare expenses related to pollution-related diseases.

FAQ

Q1: What types of dust collectors are most commonly used in steel plants?

A1: The most common types of dust collectors used in steel plants include baghouse dust collectors, cyclone separators, and electrostatic precipitators. These systems are designed to handle large volumes of particulate matter and high-temperature gases.

Q2: How do dust collectors improve energy efficiency in industrial settings?

A2: Dust collectors can recover and reuse exhaust gases, which can be used for heating or power generation. This reduces the energy consumption of the plant and lowers the environmental impact.

Q3: Can dust collectors help industries meet environmental regulations?

A3: Yes, dust collectors play a critical role in helping industries comply with environmental regulations by capturing and removing particulate matter from exhaust gases, ensuring that emissions are within legal limits.

Q4: What maintenance is required for dust collection systems?

A4: Regular maintenance of dust collectors includes cleaning filters, inspecting fans and ducts, and ensuring that the system is operating at peak efficiency. This helps extend the life of the equipment and maintain its performance.

Q5: How do dust collectors contribute to the safety of industrial workers?

A5: By removing harmful dust and particulate matter from the air, dust collectors help create a safer working environment. This reduces the risk of respiratory issues and other health problems caused by prolonged exposure to industrial pollutants.

Conclusion

Dust collectors are indispensable tools in modern industrial settings, playing a crucial role in reducing air pollution. Their ability to capture and remove harmful particulate matter and gases from exhaust streams contributes to cleaner air, safer workplaces, and more sustainable industrial operations.

English

English Français

Français عربى

عربى 简体中文

简体中文