How to Choose the Right Bag Filter Dust Collector for Your Facility?

By Admin

By Admin

Dust collectors play a pivotal role in maintaining a clean, safe, and productive work environment, especially in industries such as steel manufacturing, sand plant, foundry industry, metallurgy industry, and coking plant. An effective dust collection system prevents dust buildup, reduces potential health risks, and ensures compliance with emission standards. However, determining the correct size and type of dust collector for your facility requires a careful evaluation of several factors.

Understanding the Role of a Bag Filter Dust Collector

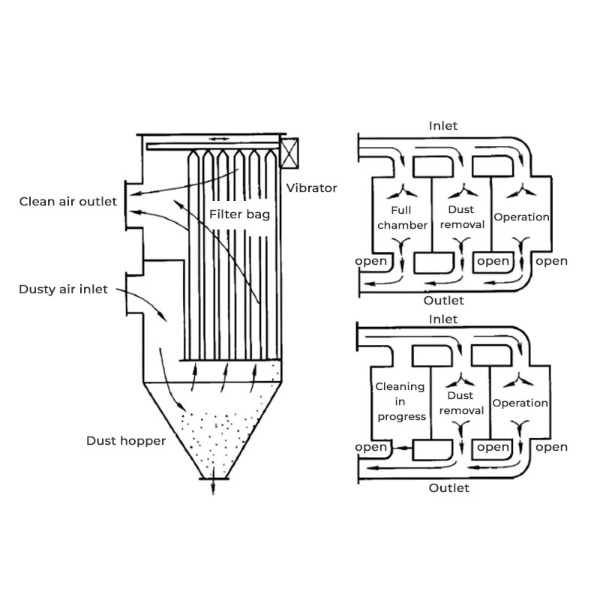

A bag filter dust collector utilizes a series of fabric filter bags to remove particulate matter from the gas stream. This type of dust collector is ideal for industries where fine, dry, non-fibrous dust is generated. The dust-laden gas enters the collector and passes through the filter bags, where larger particles settle at the bottom of the hopper, while finer particles are captured by the filter fabric. The gas is then purified, ensuring that the emissions meet environmental standards.

Key features of a bag filter dust collector include:

- High-efficiency filtration for fine, dry particles

- Pulse jet cleaning system that restores the filter’s efficiency by periodically blowing off accumulated dust

- Customization options for varying temperatures, dust concentrations, and gas properties

Factors to Consider When Choosing a Dust Collector

Choosing the right bag filter dust collector involves a comprehensive analysis of your facility’s dust-generating processes. The following factors must be considered:

a) Type and Volume of Dust Generated

The first step in selecting a dust collector is to understand the type and volume of dust your facility produces. Different dust types (e.g., wood dust, metal dust, or cement dust) require varying filtration capabilities. It’s essential to consider the following:

- Particle size and distribution: Finer dust particles demand higher filtration efficiency.

- Chemical composition: Some dusts may be hazardous or combustible, which would require specialized filters and safety features.

- Moisture content: Dust with high moisture content may require additional precautions to prevent clogging or sticking to the filter bags.

b) Airflow Requirements

To determine the correct airflow capacity (measured in cubic feet per minute or CFM), you need to calculate the airflow for each machine or dust-producing station in your facility. This calculation will be based on:

- Equipment type: The airflow requirements for each piece of equipment, such as CNC machines, saws, or planers, must be calculated.

- Hood size: The size of the hood used to capture the dust will affect the airflow needed for proper collection.

- Capture velocity: The velocity at which the dust is captured by the system’s hoods and ducts will impact the total airflow requirements.

c) Filtration Area and Type

A bag filter dust collector works by passing dusty air through a set of filter bags. The size and number of these bags depend on:

- Filtration area: The total surface area of the filter bags determines how much dust the system can handle before the filter needs cleaning.

- Type of bag: The material of the filter bag (e.g., woven or felt fabric) is chosen based on the dust type and operational conditions. For example, a polyester bag may be used for dry dust, while a nomex bag could be selected for high-temperature applications.

d) Operating Conditions and Maintenance

A good dust collector should require minimal maintenance while ensuring consistent performance. Key operational conditions to consider include:

- Temperature and humidity: Ensure the bag filter is suitable for the operating temperature (up to 250°C in some cases) and the moisture levels in the gas stream.

- Cleaning mechanism: The dust collector should have a reliable pulse jet cleaning system that uses compressed air to blow off the dust from the filter bags, preventing clogging.

e) Space and Layout

Consider the available space for installing the dust collector and the configuration of your facility. Some installations may require modifications to accommodate the dust collection system. Additionally, ensure that the dust collector’s size and structure are suitable for future growth if you anticipate expansion.

Choosing the Right Size for Your Dust Collector

After evaluating the dust type, airflow requirements, and operational conditions, the next step is to determine the size of the dust collector. The size is primarily determined by the total airflow required to handle the dust load in your facility. Here’s how you can estimate the right size:

a) Calculating the Total Airflow

To estimate the total airflow needed, sum the airflow requirements of all dust-producing equipment in your facility. Consider whether the equipment operates continuously or intermittently, as this will affect the overall demand for dust collection.

b) Considering Filter Area

The filter area is calculated based on the desired airflow and the type of dust being filtered. Typically, for each unit of airflow, you will need a certain square footage of filter media. This is where professional guidance can be helpful, as the relationship between airflow and filter area can be complex.

c) Adjusting for Future Growth

If your facility is expected to expand or if additional dust-producing equipment will be added in the future, it’s important to size the dust collector with some margin for growth. Opt for a system that allows for easy upgrades or one that can be configured with modular components.

Advantages of Using a Bag Filter Dust Collector

A bag filter dust collector offers several benefits:

- Ultra-low emissions: Achieves emission concentrations as low as 8 mg/Nm3, ensuring compliance with environmental standards.

- Energy-efficient operation: The pulse-jet cleaning mechanism reduces energy consumption by cleaning the filters only when necessary.

- Long-lasting filters: With proper maintenance, filter bags can provide long-term service, reducing the need for frequent replacements.

Additional Considerations

When selecting a bag filter dust collector, ensure you also address:

- Combustible dust: If your facility generates combustible dust, special safety features must be incorporated, such as explosion venting or spark detection systems.

- Space constraints: In some cases, dust collectors can be designed in a modular structure to fit your space requirements.

- Customization: Customizable components, such as filter materials, pulse valves, and storage hoppers, ensure the system is tailored to your specific needs.

Example Scenario: Choosing the Right Dust Collector for a Facility

Let’s walk through a typical example scenario to illustrate the process of selecting a dust collector.

Facility Overview: A medium-sized metalworking shop generates various dust types, including steel shavings, sanding dust, and welding fumes. The shop consists of several machines, including a CNC machine, a grinder, and a welding station. The shop operates on two shifts, 8 hours a day, with 10 employees.

Airflow Calculation:

- CNC machine: 500 CFM

- Grinder: 350 CFM

- Welding station: 450 CFM

Total airflow requirement: 1300 CFM

Collector Type: Given the nature of the dust (metal and welding fumes), a bag filter dust collector is chosen. This type of collector efficiently captures both fine metal dust and larger particles, ensuring a clean working environment.

Size Selection: With a total airflow requirement of 1300 CFM, a collector with an AMR (air-to-media ratio) of 7:1 is selected. This results in a filter area of approximately 185 square feet. The system is designed with pulse jet cleaning and modular components for easy maintenance and future expansion.

FAQ

Q1: What industries benefit from bag filter dust collectors?

Bag filter dust collectors are suitable for a variety of industries, including steel manufacturing, cement production, food processing, and waste incineration.

Q2: How do I know if my dust is combustible?

Combustible dust can pose serious risks. If your facility handles metal dust, wood dust, or other organic materials, consult with a professional to assess the combustibility of your dust.

Q3: How often do I need to clean the filter bags?

The pulse jet system cleans the filter bags periodically. The frequency depends on the dust load and the operational conditions. For high-dust environments, cleaning may occur more often.

Q4: Can a bag filter dust collector handle humid or wet dust?

Bag filter dust collectors are not suitable for handling flue gases with high moisture content. For wet or sticky dust, consider using a different type of filtration system.

Q5: What is the expected lifespan of a bag filter?

With proper maintenance, a filter bag can last several years. Regular cleaning and monitoring are essential to prolong the life of the filters.

English

English Français

Français عربى

عربى 简体中文

简体中文