How Do Dust Filters Improve Furnace Efficiency and Air Quality?

By Admin

By Admin

Introduction

In industrial settings, particularly in furnaces used for metal refining and processing, maintaining air quality and reducing emissions are crucial for both operational efficiency and compliance with environmental standards. Dust filters play an essential role in this regard, capturing harmful particulate matter before it is released into the atmosphere. These filters contribute to the longevity of furnace equipment, protect the health of workers, and help industries meet increasingly stringent environmental regulations.

Understanding Dust Filters in Industrial Furnaces

Definition and Basic Functioning of Industrial Dust Filters

Dust filters are mechanical or electrostatic systems designed to capture particulate matter, dust, and other airborne contaminants from industrial processes. The primary function of these filters is to improve air quality, reduce the risk of contamination, and prevent the release of hazardous dust into the environment. They operate by filtering exhaust gases through various types of media, which could include fabric bags, electrostatic charges, or cyclonic action, depending on the specific furnace requirements.

Common Types of Dust Filters Used in Furnaces

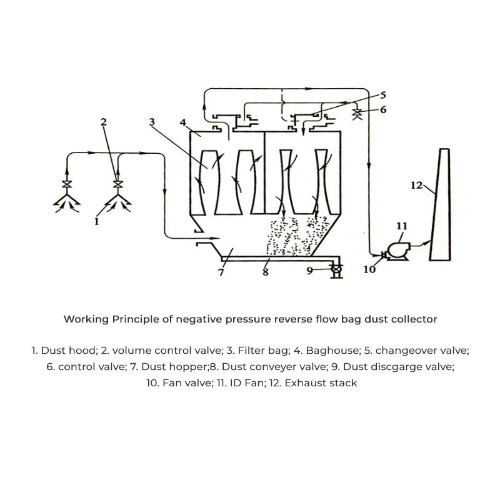

- Bag Filters: These filters consist of fabric bags that trap particles as gas passes through. They are often used in applications where fine particulate matter needs to be captured.

- Electrostatic Precipitators: These use electrical fields to charge particles, which are then collected on oppositely charged plates. These are especially effective in controlling fine particulate emissions.

- Cyclone Separators: Using centrifugal force, these filters spin exhaust gases to separate larger particles from the air. Cyclone separators are commonly used in combination with other filtration methods to achieve higher efficiency.

Key Applications of Dust Filters in Different Furnace Types

Converter Refining

In converter refining, dust filters serve a critical role in managing the intense smoke and particulate matter generated during the metal refinement process. The high temperatures in these furnaces often lead to the creation of fine dust, which can affect both the environment and furnace performance. Dust filters efficiently remove these particles, ensuring that the surrounding atmosphere remains free from harmful pollutants while improving the operational efficiency of the furnace.

Oxygen Bottom Blowing Furnace (QSL Furnace)

Oxygen bottom blowing furnaces, commonly used in steel production, are known for their unique processes that involve high oxygen injection to facilitate combustion. Dust filters in this setting are designed to manage the significant amount of particulate matter produced during the process. The high oxygen content can lead to the formation of very fine particles, which require highly efficient filtration systems to maintain air quality and prevent damage to furnace components.

Reverberatory Furnace

Reverberatory furnaces are primarily used for the melting of metals, where heat is radiated onto the material from the furnace’s roof. The filtering of dust in reverberatory furnaces is crucial not only for air quality but also for protecting the delicate furnace linings. As metal particles vaporize and cool, they can condense into fine dust. Dust filters in these furnaces help capture these particles, improving air quality and ensuring that harmful emissions are reduced to acceptable levels.

Sealed Blast Furnace / ISP Furnace

Sealed blast furnaces and ISP furnaces are used in iron and steelmaking, with a focus on optimizing fuel efficiency. These furnaces operate under pressure, which makes the control of particulate matter particularly challenging. Dust filters are essential in these systems to capture fine particles that would otherwise escape into the environment. By preventing the release of these particles, dust filters not only comply with regulatory standards but also protect furnace integrity from excessive wear.

Cupola Furnace

Cupola furnaces, used primarily in foundries for melting cast iron, generate a significant amount of smoke and particulate matter. The use of dust filters in these furnaces helps to contain the particulate load, ensuring that the molten metal can be produced without excessive airborne contamination. Additionally, by reducing the amount of particulate matter in the air, these filters improve overall safety in the foundry environment.

Zinc Furnace

Zinc furnaces, used in the extraction and refining of zinc, create heavy fumes due to the high temperature processes involved. Dust filters are vital in controlling emissions in zinc smelting operations. These filters are designed to capture both the fine dust generated from zinc ores and the smoke produced during the refining process. By efficiently filtering these particles, dust filters help to reduce environmental impact and improve the longevity of the furnace equipment.

Benefits of Using Dust Filters in Industrial Furnaces

Environmental Benefits

Dust filters significantly reduce the amount of particulate matter released into the atmosphere. This helps industries meet stringent environmental regulations aimed at controlling air pollution. By trapping harmful dust, these filters prevent contaminants from polluting the surrounding air, contributing to cleaner environments.

Operational Benefits

In addition to environmental benefits, dust filters improve the operational efficiency of furnaces. By removing particulate matter from the exhaust gases, they prevent the buildup of dust on furnace components, which can lead to blockages, inefficiencies, and costly maintenance. Dust filters also help to ensure that furnace operations remain smooth, minimizing downtime and improving throughput.

Health and Safety

Protecting workers from exposure to industrial dust is a major concern in many industrial processes. Dust filters capture hazardous particles before they can enter the workspace, reducing the risk of respiratory issues and other health concerns for workers. This is especially important in industries like metal refining, where fine dust can contain toxic substances.

Advanced Dust Filtration Technologies

Latest Innovations in Dust Filter Technology

The field of dust filtration technology has seen significant advancements in recent years. Modern filters are designed to capture smaller particles, improve energy efficiency, and reduce maintenance costs. New materials, such as nanofibers and advanced ceramic filters, are increasingly being used to provide more efficient filtration solutions.

The Role of IoT and Smart Technology

Internet of Things (IoT) and smart technologies are beginning to play a role in dust filter optimization. Sensors integrated into the filtration system can monitor airflow, pressure, and dust accumulation, allowing for predictive maintenance and real-time performance adjustments. This ensures that filters operate at maximum efficiency and reduces the need for manual intervention.

AI and Machine Learning for Predictive Maintenance

Artificial Intelligence (AI) and machine learning algorithms are being implemented to predict when a dust filter needs maintenance or replacement. By analyzing patterns in dust accumulation and performance data, these technologies can forecast when filters will need servicing, preventing unexpected failures and reducing downtime.

Challenges and Solutions in Dust Filter Applications

Common Issues

While dust filters are crucial for controlling emissions and improving furnace efficiency, they are not without challenges. Clogging, short filter lifespans, and high maintenance costs are common issues faced by many industries. Filters may also struggle to handle extreme temperatures or high volumes of particulate matter.

Solutions to Common Problems

Technological advancements in materials and filter designs are helping to overcome these challenges. High-temperature resistant materials, such as ceramic fibers, have been developed to withstand harsher conditions. Additionally, regular maintenance schedules and smart monitoring systems can help ensure that filters are operating efficiently and effectively.

Conclusion

Dust filters are integral to modern industrial furnace operations, providing vital environmental, operational, and safety benefits. As technology continues to evolve, these filters will become even more efficient, helping industries meet regulatory standards and improve operational efficiency. By understanding the role and capabilities of dust filters, businesses can make informed decisions to ensure their furnaces operate smoothly and sustainably.

FAQ

1. What is the role of a dust filter in a furnace?

Dust filters capture particulate matter and contaminants in furnace exhaust, improving air quality and preventing the release of harmful emissions.

2. Why are dust filters important for oxygen bottom blowing furnaces (QSL furnaces)?

These furnaces generate fine particulate matter, which requires highly efficient filtration systems to maintain air quality and prevent furnace damage.

3. How does dust filtering help in improving the performance of a reverberatory furnace?

By capturing particles that could clog or damage the furnace, dust filters ensure consistent operation and prevent contamination in the molten metal.

4. What challenges do dust filters face in cupola furnaces, and how are they addressed?

Cupola furnaces generate large amounts of smoke and particulate matter, but modern filters are designed to efficiently capture these particles while maintaining furnace throughput.

5. Can dust filters reduce the overall cost of furnace operation?

Yes, by improving efficiency and reducing downtime, dust filters help extend the lifespan of furnace components and reduce maintenance costs, ultimately leading to cost savings.

English

English Français

Français عربى

عربى 简体中文

简体中文