-

Top 5 Common Problems with Dust Control Systems and How to Fix Them

Dust control systems are integral to maintaining clean air and preventing pollution in various industrial sectors. A well-designed dust control system is essential for minimizing hazardous airborne particles, ensuring compliance with environmental regulations, and improving workp...

-

Bag Filters vs. Cartridge Filters: Which is Better for Your System?

Introduction In industries where air pollution control and waste gas treatment are crucial, selecting the right type of dust filter is essential for both operational efficiency and environmental responsibility. Among the various filtration systems, bag filters and cartridge filte...

-

The Role of Bag Filters in Preventing Air Pollution: Key Benefits and Applications

Introduction Air pollution remains a significant global concern, especially in industrial environments where the emissions of particulate matter, harmful gases, and toxins are frequent. Effective air pollution control systems are crucial to ensuring that industries comply with en...

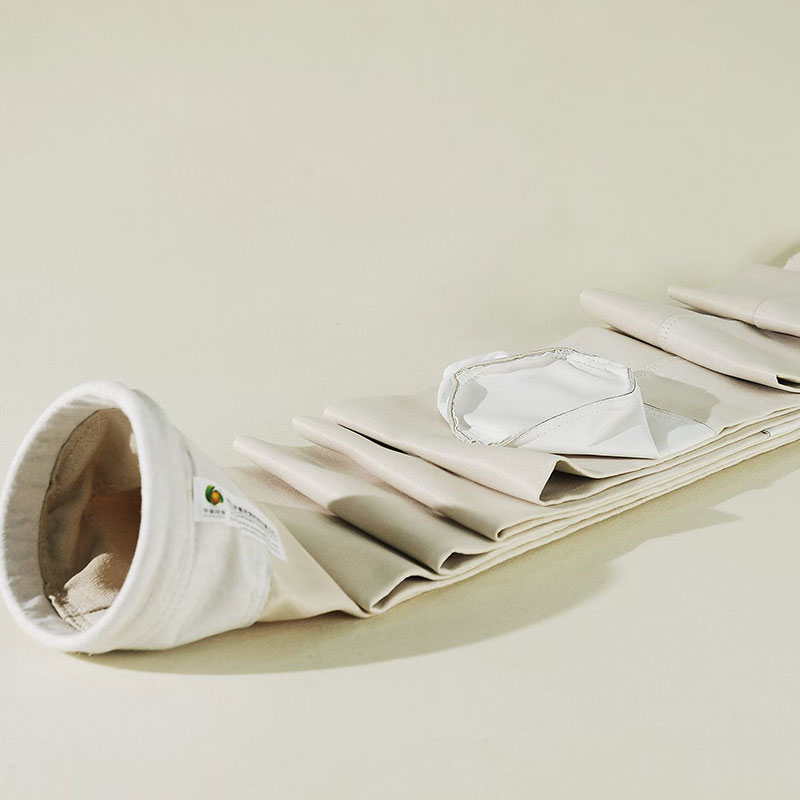

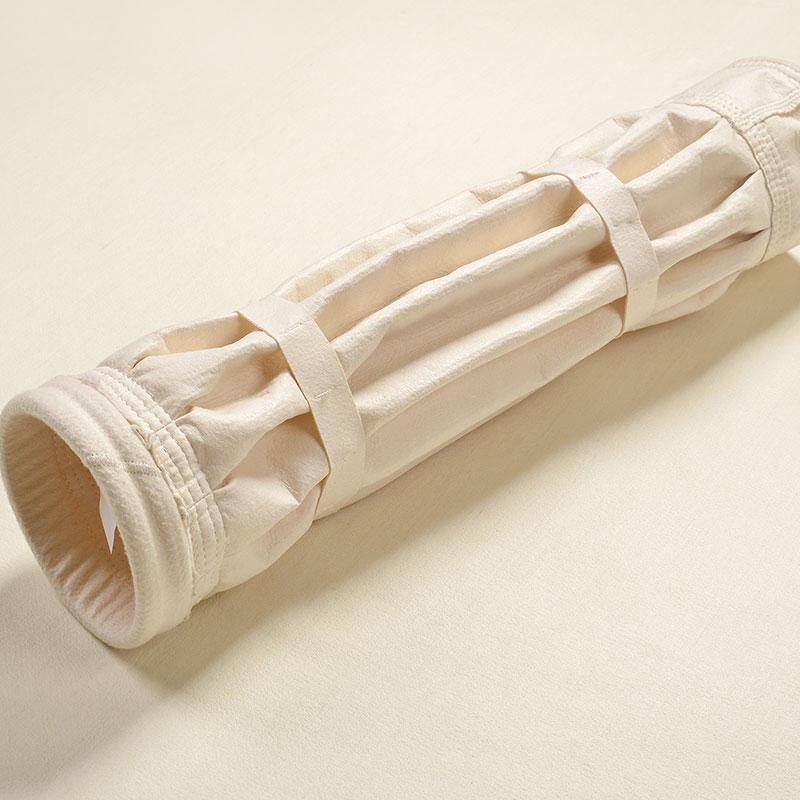

What’s the difference between woven and non-woven dust filter bags?

1. Introduction to Dust Filter Bags in Industrial Filtration

- Definition and role of dust filter bags in air pollution control systems.

- Overview of industrial applications (steel, cement, pharmaceuticals, etc.), aligning with Anhui Tiankang’s expertise in dust removal systems for sectors like steelmaking, foundries, and VOC treatment.

- Importance of material selection (woven vs. non-woven) for efficiency and compliance with environmental standards.

2. Woven Dust Filter Bags: Structure and Applications

- Material Composition: Yarn types (e.g., polyester, PTFE), weaving techniques (plain, twill weave), and surface treatments (e.g., calendering).

- Performance Characteristics:

- High mechanical strength and temperature resistance.

- Ideal for heavy-load industries (e.g., steel industry sintering, blast furnace tapping hoods).

- Limitations: Lower fine-particle retention compared to non-woven alternatives.

3. Non-Woven Dust Filter Bags: Technology and Advantages

- Manufacturing Processes: Needle punching, meltblown, or spunbond methods.

- Key Properties:

- Superior filtration efficiency for submicron particles (critical for pharmaceutical or cement industries).

- Flexibility in material blends (e.g., hybrid fibers for corrosive environments like non-ferrous smelting).

- Trade-offs: Reduced durability under high abrasive conditions.

4. Comparative Analysis: Woven vs. Non-Woven

(Use a concise table for clarity, if needed)

| Parameter | Woven Dust Filter Bags | Non-Woven Dust Filter Bags |

|---|---|---|

| Filtration Efficiency | Moderate (10–50 µm) | High (<5 µm) |

| Temperature Range | Up to 280°C (PTFE) | Typically ≤150°C (varies by material) |

| Primary Use Cases | Heavy dust loads (e.g., steel slag treatment) | Fine particulate (e.g., VOC systems) |

5. Selection Criteria for Industrial Scenarios

- Factors influencing choice:

- Dust particle size (linked to Anhui Tiankang’s customized hood designs for electric furnaces or converters).

- Chemical resistance (e.g., acidic flue gases in desulfurization towers).

- Operational lifespan and maintenance (e.g., ash conveying equipment compatibility).

- Emphasis on ISO-certified testing and patented technologies for optimal performance.

6. Innovations and Future Trends

-

Advances in hybrid materials (e.g., PTFE-coated woven bags) for flue gas denitrification.

-

Role of full-chain quality systems (R&D to delivery) in enhancing durability.

-

Summary of woven/non-woven distinctions.

-

Reiteration of dust filter bags as critical components in turnkey environmental projects, supported by engineering expertise like Anhui Tiankang’s integrated solutions.

English

English Français

Français عربى

عربى 简体中文

简体中文