-

Top 5 Common Problems with Dust Control Systems and How to Fix Them

Dust control systems are integral to maintaining clean air and preventing pollution in various industrial sectors. A well-designed dust control system is essential for minimizing h...

-

Bag Filters vs. Cartridge Filters: Which is Better for Your System?

Introduction In industries where air pollution control and waste gas treatment are crucial, selecting the right type of dust filter is essential for both operational efficiency and...

-

The Role of Bag Filters in Preventing Air Pollution: Key Benefits and Applications

Introduction Air pollution remains a significant global concern, especially in industrial environments where the emissions of particulate matter, harmful gases, and toxins are freq...

-

A Step-by-Step Guide to Maintaining Your Electrostatic Precipitator

An electrostatic precipitator (ESP) is a crucial component in industrial processes that need to control particulate pollution, particularly in power plants, cement factories, and o...

Industrial Wet Type Dust Collector Factory

Due to different on-site environments, some dust is wet flue gas with extremely high water content, which makes it impossible to use bag or cartridge dust collectors. In this case, a wet dust collector must be used. The wet dust collector uses multi-stage filtration (water film adsorption-water bath flushing-demister and other multi-stage filtration methods) to ensure that the particulate matter in the flue gas meets the emission standards for discharge. The wet dust collector has high dust removal efficiency and can reduce the temperature of high-temperature dusty flue gas. For toxic flue gas, the toxicity of the flue gas can be reduced by washing and cooling with water.

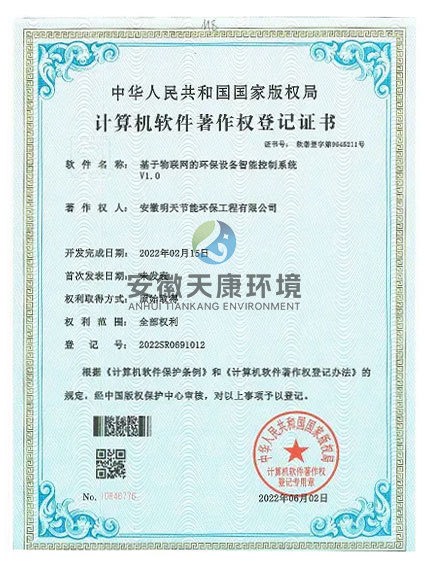

Anhui Tiankang Environmental Technology Co., Ltd. (formerly Wuxi Mingtian Environmental Protection Equipment Co., Ltd.) was established in 2002. It is a private high-tech enterprise dedicated to environmental protection and governance. The company is mainly engaged in environmental engineering design, environmental protection facility operation and environmental pollution control technology research and development, and undertakes various dust removal systems, flue gas desulfurization and denitrification systems and VOC systems and other engineering general contracting business. We are Customized Industrial Wet Type Dust Collector Factory and China Industrial Wet Type Dust Collector Contractor, At present, the company's products include various bag dust collector systems (including raw materials, batching, pelletizing, sintering, ironmaking, steelmaking, rolling and other aspects of steel mills; foundry industry, pharmaceutical industry, glass industry, cement industry, non-ferrous metal smelting industry, etc.), converter primary dust removal flue gas recovery system, slag treatment system, VOC treatment system (including activated carbon adsorption device, catalytic combustion device, RTO and UV pretreatment + zeolite wheel adsorption + RCO device, etc.), as well as flue gas heat exchanger, cooler, capture hood (including electric furnace fully enclosed hood, roof hood, converter front and rear hood, blast furnace tapping port, slag skimmer hood, various belt hoods, and various scattered point hoods in steelmaking workshop, etc.), mobile ventilation slots, mufflers, desulfurization towers, ash conveying equipment, ventilation duct flexible compensators, pipeline sliding supports, condensate drainers, bags, keels and other customized accessories.

Tiankang Environment has two branches. One is Wuxi Mingtian Environmental Protection Equipment Co., Ltd., which is located in Wuxi, a famous city in the south of the Yangtze River with a developed economy and picturesque scenery. It has convenient transportation and rich natural and cultural landscapes. The other is Anhui Tiankang Environmental Technology Co., Ltd. (formerly Anhui Mingtian Energy Saving and Environmental Protection Engineering Co., Ltd.), which is located in Lu'an, an old revolutionary base with a long history, mountains and water, and a pleasant climate. The company sincerely welcomes friends from all walks of life to visit and guide with an open attitude. It is willing to provide technical services for all walks of life and provide a stage for people with lofty ideals to display their wisdom and talents.

The company focuses on the future, is determined to protect the environment, and regards returning a fresh, blue and clear sky to mankind as the company's goal!

Innovation Trends and Intelligent Development of Wet Dust Collection Technology Under Upgraded Environmental Policies

With increasingly stringent global environmental policies and higher standards for industrial dust control, wet dust collection technology has been widely adopted in highly polluting industries such as steel, chemicals, and cement due to its efficiency, safety, and adaptability. As a leading enterprise in China's environmental protection sector, Anhui Tiankang Environmental Technology Co., Ltd. leverages years of technical expertise and market demands to drive innovation and intelligent upgrades in wet dust collection technology, helping industries achieve green production.

1. High-Efficiency Energy-Saving Design: Reducing Energy Consumption and Operating Costs

Traditional wet dust collectors face challenges such as high energy consumption and significant water usage. Tiankang Environment optimizes spray systems, improves airflow distribution design, and incorporates high-efficiency water pumps and low-resistance structures to significantly reduce operational energy consumption. For example, in dust collection projects for steel industry sintering machines, the adoption of recirculating water systems + high-efficiency nozzles achieves water savings of over 30% while reducing secondary sludge treatment burdens.

2. Anti-Corrosion and Material Innovation: Enhancing Equipment Durability

Wet dust collectors are constantly exposed to high humidity, acidic, or alkaline gases, leading to corrosion risks. Tiankang Environment employs corrosion-resistant materials such as PP (polypropylene), FRP (fiberglass-reinforced plastic), and stainless steel 316L, along with nano-coating technology, to extend equipment lifespan. In VOC treatment projects for the chemical industry, customized anti-corrosion solutions have increased equipment service life to over 10 years.

3. Wastewater Recycling and Zero-Discharge Technology: Complying with Environmental Policies

Environmental regulations impose strict requirements on industrial wastewater discharge. Tiankang Environment has developed a multi-stage sedimentation + flocculation purification system to enable wastewater recycling, minimizing freshwater consumption. Additionally, integrated sludge dewatering equipment compresses collected dust into compact blocks for easy recovery or safe disposal, meeting "zero-waste factory" standards.

4. Intelligent Control: IoT and Remote Monitoring

Utilizing IoT technology, Tiankang Environment has introduced an intelligent wet dust collection system that monitors real-time parameters such as dust concentration, water pressure, and pH levels, enabling remote adjustments via cloud platforms. For instance, in cement plant applications, the smart system automatically regulates spray intensity to maintain dust collection efficiency above 99% while reducing manual maintenance costs.

5. Industry-Specific Customized Solutions: Meeting Diverse Sector Needs

Tiankang Environment provides tailored solutions for different industries:

- Steel Industry: For high-temperature flue gas, combines flue gas coolers with wet dust collection to prevent equipment damage.

- Mining and Cement Industry: For high-concentration dust, adopts multi-stage spray + Venturi enhancement technology to ensure compliance with emission standards.

- Chemical Industry: Integrates VOC treatment units (e.g., RTO, activated carbon adsorption) for combined dust and exhaust gas treatment.

Tiankang Environment: Driving a Green Future Through Technology

Since its establishment in 2002, Anhui Tiankang Environmental Technology Co., Ltd. has remained committed to technological innovation in environmental protection, offering end-to-end services from engineering design to equipment manufacturing. With the mission of "returning a fresh blue sky to humanity," the company continuously advances wet dust collection technology to help clients meet environmental challenges and achieve sustainable development. Moving forward, Tiankang Environment will further explore low-carbon, intelligent, and integrated dust collection solutions to contribute to global industrial environmental protection.

(For specific case studies or technical parameters, please contact Tiankang Environment's professional team for customized solutions.)

Five Comprehensive Industry Knowledge Topics Integrating Wet Dust Collection Technology with Tiankang's Expertise

1. Advanced Steel Mill Dust Control: Tiankang's Wet Scrubber Solutions for Sintering & Steelmaking

Modern steel plants face increasingly stringent emission regulations, particularly for fine particulate matter (PM2.5) and heavy metals. Tiankang's wet dust collection systems employ multi-stage scrubbing technology combining venturi scrubbers with packed bed towers to achieve >99.9% efficiency on submicron particles. Our proprietary nozzle designs feature anti-clogging ceramic inserts and adjustable spray patterns to handle varying gas volumes in sintering machine applications. For basic oxygen furnace (BOF) primary dedusting, we integrate steam condensation chambers to prevent white plume formation while recovering waste heat. All systems utilize FRP/PP composite materials with fiber-reinforced structural supports to withstand the corrosive high-temperature (up to 400°C quenched) environment.

Case Study: At a major Chinese steel group's 450m² sintering plant, our customized wet ESP system reduced emissions to <10mg/Nm³ while recovering 85% of process water through advanced lamella clarifiers and automatic sludge dewatering. The installation features our SmartScrub™ control system that dynamically adjusts water flow based on real-time opacity monitor feedback, achieving 22% energy savings versus conventional designs.

2. Combustible Dust Safety: Wet Collection Systems for Explosion-Prone Industries

Combustible dust incidents cause hundreds of industrial accidents annually. Tiankang's ATEX-certified wet collectors incorporate multiple safety layers: conductive HDPE construction with grounding continuity monitoring, nitrogen inerting systems for collection hoppers, and high-speed deluge valves that activate within 50ms of spark detection. For aluminum polishing applications, we use abrasion-resistant silicon carbide nozzles and pH-controlled recirculation water to prevent hydrogen gas accumulation. Our explosion venting calculations follow NFPA 68 standards with rupture panels directing forces to safe discharge areas.

Technical Innovation: The patented Tiankang Anti-Deflagration Wet Collector features a labyrinthine gas path design that quenches flame propagation through rapid heat absorption in the water curtain. Third-party testing at the China Academy of Safety Science demonstrated effective suppression of dust explosions with Kst values up to 300 bar·m/s.

3. Integrated Air Pollution Control: Combining Wet Dust Collectors with VOC Treatment

Many industrial processes generate both particulate and gaseous pollutants. Tiankang's integrated systems first remove particulates via wet collection, then treat VOCs through optimized combinations of technologies: For low-concentration (<500mg/m³) intermittent flows, we recommend activated carbon adsorption with our self-cleaning pulsed-jet regeneration system. Medium concentrations (500-5,000mg/m³) benefit from catalytic oxidation (RCO) using our proprietary rare-earth doped catalysts that resist sulfur poisoning. High-concentration streams (>5,000mg/m³) employ thermal oxidizers (RTO) with heat recovery efficiencies up to 95% through ceramic honeycomb heat exchangers.

System Synergy: In a recent coating plant project, our "Wet+RCO" configuration achieved particulate emissions <5mg/m³ and VOC destruction efficiency >98%, while the heat recovery from the RCO preheats the scrubber makeup water, reducing total energy consumption by 30% compared to separate systems.

4. Water Conservation in Dust Collection: Tiankang's Closed-Loop Recycling Systems

Water scarcity drives innovation in wet scrubber operations. Our water management solutions include: Automated blowdown control based on conductivity measurements, spiral sludge concentrators that reduce water content in waste solids to <65%, and advanced filtration using backwashable sintered polyethylene membranes. For zero liquid discharge (ZLD) requirements, we incorporate mechanical vapor recompression (MVR) evaporators that recover >95% of water while crystallizing salts for safe disposal. The entire water treatment skid is PLC-controlled with cloud-based performance monitoring.

Performance Data: At a Gansu province cement plant in arid conditions, our ZLD system processes 50m³/hr of scrubber blowdown with specific energy consumption of 35kWh/m³ - 40% lower than conventional thermal evaporators. The recovered water meets GB/T 19923-2005 reuse standards for industrial processes.

5. Smart Maintenance Strategies for Industrial Wet Scrubbers

Predictive maintenance transforms wet scrubber reliability. Tiankang's IoT-enabled systems feature: Vibration analysis modules on critical pumps detecting bearing wear 3-6 months before failure, ultrasonic nozzle monitors identifying partial blockages through spray pattern analysis, and corrosion rate probes using linear polarization resistance (LPR) technology. Our cloud platform applies machine learning to predict optimal maintenance windows, reducing downtime by up to 60%. Field technicians access AR-guided repair procedures through ruggedized tablets, with real-time support from our 24/7 engineering center.

Digital Twin Application: A copper smelter using our smart maintenance system achieved 92% schedule compliance and 75% reduction in emergency repairs. The digital twin model accurately predicted pump seal failures with 87% confidence 120 days in advance, allowing planned shutdown coordination with production schedules.

English

English Français

Français عربى

عربى 简体中文

简体中文