-

Top 5 Common Problems with Dust Control Systems and How to Fix Them

Dust control systems are integral to maintaining clean air and preventing pollution in various industrial sectors. A well-designed dust control system is essential for minimizing h...

-

Bag Filters vs. Cartridge Filters: Which is Better for Your System?

Introduction In industries where air pollution control and waste gas treatment are crucial, selecting the right type of dust filter is essential for both operational efficiency and...

-

The Role of Bag Filters in Preventing Air Pollution: Key Benefits and Applications

Introduction Air pollution remains a significant global concern, especially in industrial environments where the emissions of particulate matter, harmful gases, and toxins are freq...

-

A Step-by-Step Guide to Maintaining Your Electrostatic Precipitator

An electrostatic precipitator (ESP) is a crucial component in industrial processes that need to control particulate pollution, particularly in power plants, cement factories, and o...

Industrial Cartridge Dust Collector Filter Factory

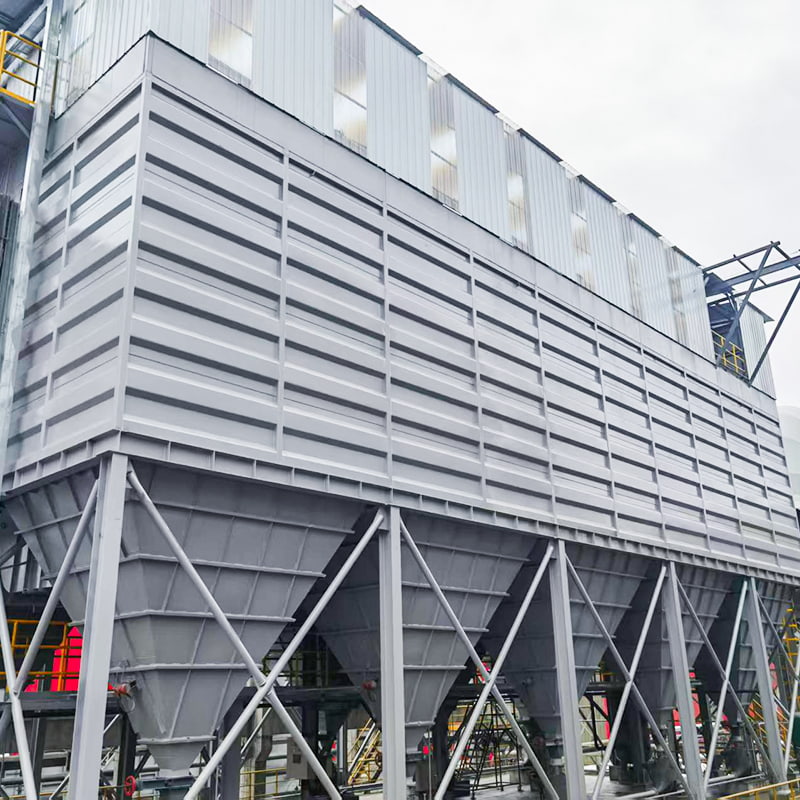

The filtering principle of the cartridge dust collector is the same as that of the bag dust collector, except that the bags are replaced with cartridges. The maximum filtering area of a single φ160*3000 cartridge can be designed to be 6.9m2, while the filtering area of a single φ160*6000 bag is only 3m2. Therefore, using cartridges as filtering equipment can not only save space and reduce the initial cost investment, but also greatly reduce subsequent operation and maintenance costs.

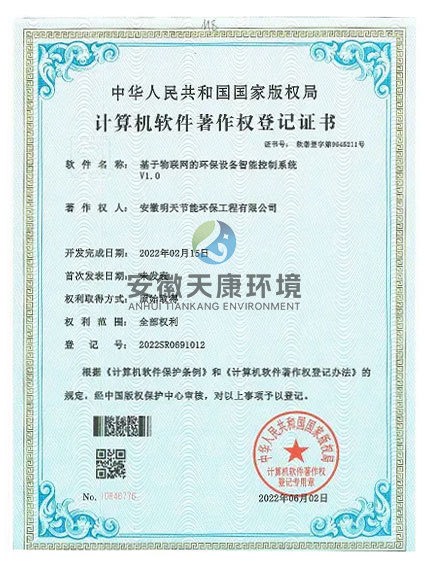

Anhui Tiankang Environmental Technology Co., Ltd. (formerly Wuxi Mingtian Environmental Protection Equipment Co., Ltd.) was established in 2002. It is a private high-tech enterprise dedicated to environmental protection and governance. The company is mainly engaged in environmental engineering design, environmental protection facility operation and environmental pollution control technology research and development, and undertakes various dust removal systems, flue gas desulfurization and denitrification systems and VOC systems and other engineering general contracting business. We are Customized Industrial Cartridge Dust Collector Filter Factory and China Industrial Cartridge Dust Collector Filter Contractor, At present, the company's products include various bag dust collector systems (including raw materials, batching, pelletizing, sintering, ironmaking, steelmaking, rolling and other aspects of steel mills; foundry industry, pharmaceutical industry, glass industry, cement industry, non-ferrous metal smelting industry, etc.), converter primary dust removal flue gas recovery system, slag treatment system, VOC treatment system (including activated carbon adsorption device, catalytic combustion device, RTO and UV pretreatment + zeolite wheel adsorption + RCO device, etc.), as well as flue gas heat exchanger, cooler, capture hood (including electric furnace fully enclosed hood, roof hood, converter front and rear hood, blast furnace tapping port, slag skimmer hood, various belt hoods, and various scattered point hoods in steelmaking workshop, etc.), mobile ventilation slots, mufflers, desulfurization towers, ash conveying equipment, ventilation duct flexible compensators, pipeline sliding supports, condensate drainers, bags, keels and other customized accessories.

Tiankang Environment has two branches. One is Wuxi Mingtian Environmental Protection Equipment Co., Ltd., which is located in Wuxi, a famous city in the south of the Yangtze River with a developed economy and picturesque scenery. It has convenient transportation and rich natural and cultural landscapes. The other is Anhui Tiankang Environmental Technology Co., Ltd. (formerly Anhui Mingtian Energy Saving and Environmental Protection Engineering Co., Ltd.), which is located in Lu'an, an old revolutionary base with a long history, mountains and water, and a pleasant climate. The company sincerely welcomes friends from all walks of life to visit and guide with an open attitude. It is willing to provide technical services for all walks of life and provide a stage for people with lofty ideals to display their wisdom and talents.

The company focuses on the future, is determined to protect the environment, and regards returning a fresh, blue and clear sky to mankind as the company's goal!

How to Choose High-Efficiency and Durable Industrial Cartridge Dust Collector Filter Media? – Professional Advice from Anhui Tiankang Environmental Technology Co., Ltd.

The core component of an industrial cartridge dust collector is the filter media, whose performance directly affects filtration efficiency, operating costs, and equipment lifespan. As a high-tech enterprise specializing in environmental protection for over 20 years, Anhui Tiankang Environmental Technology Co., Ltd. has extensive experience in filter media selection across industries such as steel, pharmaceuticals, cement, and foundry. Below are the key selection considerations:

1. Select Filter Media Based on Dust Characteristics

Polyester (PET) Fiber: Suitable for normal temperatures (≤135°C) and low-corrosivity dust (e.g., woodworking, food industry), offering cost-effectiveness.

Anti-Static Fiber: Designed for flammable and explosive dust (e.g., aluminum powder, coal dust), requiring conductive frames to prevent static buildup.

PTFE Membrane-Coated Media: Ideal for high-humidity or sticky dust (e.g., sintering fumes, chemical dust), featuring a smooth surface for easy cleaning. Anhui Tiankang has widely applied this type in steel plant sintering dust removal projects.

2. Consider Physical and Chemical Stability

Temperature Resistance: High-temperature applications (e.g., steel plant electric furnace dust) require Nomex® or P84® fibers (withstand ≥200°C).

Acid/Alkali Resistance: Chemical industries should use PTFE or specially coated media to avoid corrosion (as seen in Anhui Tiankang’s pharmaceutical industry cases).

3. Optimize Structural Design for Better Filtration

Pleat Density: High-pleat designs (e.g., Anhui Tiankang’s custom cartridges) increase filtration area, reduce pressure drop, and extend cleaning cycles.

End Cap Sealing: Polyurethane potting or metal end caps prevent air leakage (commonly used in Anhui Tiankang’s VOC treatment systems).

4. Match Filter Media with Cleaning Methods

Pulse Jet Cleaning: Requires rigid support frames (e.g., stainless steel mesh) to prevent collapse (demonstrated in Anhui Tiankang’s pulse-jet dust collectors).

Mechanical Shaking: Suitable for lightweight media but needs frequent maintenance (e.g., cement plant applications).

5. Choose a Reliable Supplier with Customization Services

As a leading customized dust removal equipment provider in China, Anhui Tiankang offers end-to-end services from media testing,工况 analysis to lifetime maintenance. For example, in steel plant blast furnace tapping point projects, the company extended cartridge lifespan to over 18 months by optimizing media weight (≥550g/m²) and coating technology.

Conclusion

Selecting high-performance filter media requires balancing dust properties, operating conditions, and cost efficiency. With cross-industry engineering expertise, Anhui Tiankang Environmental Technology Co., Ltd. delivers tailored cartridge dust collection solutions, advancing its mission to "return a fresh blue sky to humanity."

Industrial Cartridge Dust Collector Filter Selection Guide - Expert Solutions by Anhui Tiankang Environmental Technology Co., Ltd.

With over two decades of experience in environmental protection engineering, Anhui Tiankang Environmental Technology Co., Ltd. has established itself as a leading provider of industrial dust collection solutions. Our expertise spans across multiple industries including steel production, pharmaceutical manufacturing, cement processing, and non-ferrous metal smelting. This comprehensive guide will help you understand how to select the optimal cartridge filters for your specific industrial applications.

Understanding Your Dust Collection Requirements

Before selecting filter media, it's crucial to analyze your specific operational conditions. Our engineering team at Anhui Tiankang begins every project with a thorough assessment of:

Particle size distribution and dust loading characteristics

Process temperature fluctuations and peak operating temperatures

Chemical composition and potential corrosive elements in the dust stream

Moisture content and potential for condensation

Explosion risks and static electricity concerns

Advanced Filter Media Technologies

Anhui Tiankang offers a complete range of high-performance filter media options:

Nanofiber Composite Media: Our proprietary nanofiber technology provides superior surface filtration with minimal pressure drop, ideal for submicron particle capture in pharmaceutical and food processing applications.

High-Temperature Solutions: For steel mill and foundry applications, we developed special blends of meta-aramid and P84 fibers that withstand continuous operation at 200°C with intermittent peaks to 260°C.

Hydrophobic Treatments: Our special surface treatments prevent moisture absorption in cement and mineral processing applications, significantly extending filter life in humid environments.

Custom Engineering Solutions

What sets Anhui Tiankang apart is our ability to provide fully customized dust collection solutions:

Precision pleating technology that maximizes filtration area while maintaining structural integrity

Special anti-abrasion coatings for applications with highly erosive dust particles

Conductive media options with integrated grounding systems for explosive dust environments

Hybrid media constructions that combine multiple filtration mechanisms for challenging applications

Performance Optimization Strategies

Our field engineers have developed proven methods to maximize your dust collection system's efficiency:

Proper pleat count and geometry optimization based on your specific airflow requirements

Strategic media selection balancing initial cost with total lifecycle expenses

Advanced cleaning system tuning to maintain optimal pressure drop while minimizing media wear

Predictive maintenance programs that identify media replacement needs before performance degradation

Industry-Specific Applications

Steel Production: Our converter primary gas recovery systems use specially designed cartridges that handle the unique challenges of BOF gas cleaning.

Pharmaceutical: GMP-compliant cartridge solutions with FDA-approved materials for potent compound containment.

Cement: High-efficiency filters for raw mill and kiln applications with our proprietary anti-blinding technology.

Non-Ferrous Metals: Acid-resistant media formulations for aluminum, copper, and zinc processing operations.

Quality Assurance and Testing

All Anhui Tiankang filter cartridges undergo rigorous quality control:

In-house testing laboratory for media performance verification

Complete physical property testing including tensile strength and permeability measurements

Real-world simulation testing in our pilot dust collection systems

Third-party certifications for fire resistance, electrostatic properties, and chemical compatibility

Technical Support and Service

Our commitment extends beyond product delivery:

On-site system audits and performance evaluations

Filter change-out services with proper disposal of used media

Training programs for your maintenance staff

24/7 technical support hotline for emergency situations

At Anhui Tiankang Environmental Technology Co., Ltd., we combine our extensive engineering experience with cutting-edge filtration technologies to deliver dust collection solutions that meet your exact requirements. Contact our technical team today to discuss how we can optimize your cartridge filtration system for peak performance and reliability.

English

English Français

Français عربى

عربى 简体中文

简体中文