-

Top 5 Common Problems with Dust Control Systems and How to Fix Them

Dust control systems are integral to maintaining clean air and preventing pollution in various industrial sectors. A well-designed dust control system is essential for minimizing h...

-

Bag Filters vs. Cartridge Filters: Which is Better for Your System?

Introduction In industries where air pollution control and waste gas treatment are crucial, selecting the right type of dust filter is essential for both operational efficiency and...

-

The Role of Bag Filters in Preventing Air Pollution: Key Benefits and Applications

Introduction Air pollution remains a significant global concern, especially in industrial environments where the emissions of particulate matter, harmful gases, and toxins are freq...

-

A Step-by-Step Guide to Maintaining Your Electrostatic Precipitator

An electrostatic precipitator (ESP) is a crucial component in industrial processes that need to control particulate pollution, particularly in power plants, cement factories, and o...

Industrial Electrostatic Precipitator Filter Factory

An electrostatic precipitator is a device that uses electrostatic force to remove suspended particles in the air such as flue gas and industrial dust. It mainly consists of a discharge electrode and a collector. After high-voltage direct current is passed through the discharge electrode and a strong electric field is created around it, the particles in the air are charged. Each dust particle obtains the same negative charge through ionization. Based on the principle of attraction between opposite charges, the charged dust particles are attracted to the grounded collector, thereby achieving dust collection. The dust collected on the collector is collected into the ash hopper at the bottom through regular vibration or ultrasonic methods.

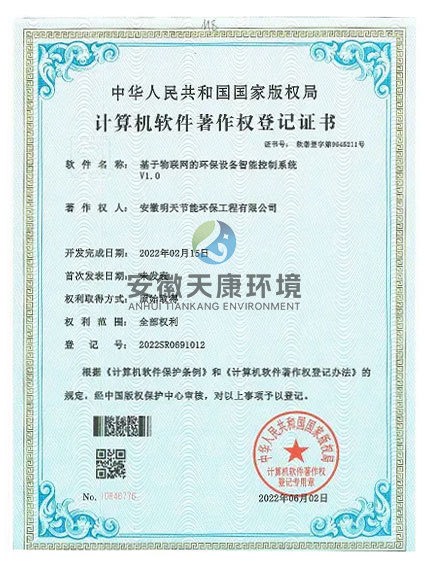

Anhui Tiankang Environmental Technology Co., Ltd. (formerly Wuxi Mingtian Environmental Protection Equipment Co., Ltd.) was established in 2002. It is a private high-tech enterprise dedicated to environmental protection and governance. The company is mainly engaged in environmental engineering design, environmental protection facility operation and environmental pollution control technology research and development, and undertakes various dust removal systems, flue gas desulfurization and denitrification systems and VOC systems and other engineering general contracting business. We are Customized Industrial Electrostatic Precipitator Filter Factory and China Industrial Electrostatic Precipitator Filter Contractor, At present, the company's products include various bag dust collector systems (including raw materials, batching, pelletizing, sintering, ironmaking, steelmaking, rolling and other aspects of steel mills; foundry industry, pharmaceutical industry, glass industry, cement industry, non-ferrous metal smelting industry, etc.), converter primary dust removal flue gas recovery system, slag treatment system, VOC treatment system (including activated carbon adsorption device, catalytic combustion device, RTO and UV pretreatment + zeolite wheel adsorption + RCO device, etc.), as well as flue gas heat exchanger, cooler, capture hood (including electric furnace fully enclosed hood, roof hood, converter front and rear hood, blast furnace tapping port, slag skimmer hood, various belt hoods, and various scattered point hoods in steelmaking workshop, etc.), mobile ventilation slots, mufflers, desulfurization towers, ash conveying equipment, ventilation duct flexible compensators, pipeline sliding supports, condensate drainers, bags, keels and other customized accessories.

Tiankang Environment has two branches. One is Wuxi Mingtian Environmental Protection Equipment Co., Ltd., which is located in Wuxi, a famous city in the south of the Yangtze River with a developed economy and picturesque scenery. It has convenient transportation and rich natural and cultural landscapes. The other is Anhui Tiankang Environmental Technology Co., Ltd. (formerly Anhui Mingtian Energy Saving and Environmental Protection Engineering Co., Ltd.), which is located in Lu'an, an old revolutionary base with a long history, mountains and water, and a pleasant climate. The company sincerely welcomes friends from all walks of life to visit and guide with an open attitude. It is willing to provide technical services for all walks of life and provide a stage for people with lofty ideals to display their wisdom and talents.

The company focuses on the future, is determined to protect the environment, and regards returning a fresh, blue and clear sky to mankind as the company's goal!

Electrostatic Precipitator vs Bag Filter: Efficiency, Cost and Environmental Performance Comparison

1. Dust Removal Efficiency Comparison

Electrostatic Precipitator (ESP):

Suitable for high-concentration, large flue gas volume dust removal (such as coal-fired power plants, steel sintering, etc.), with collection efficiency for fine particles (PM2.5) reaching over 99%. However, its performance is sensitive to dust resistivity (both too high or too low resistivity affects efficiency).

Bag Filter:

Provides higher filtration efficiency for ultrafine dust (such as in cement, pharmaceutical industries, typically >99.9%), and is not limited by dust resistivity. However, it requires regular bag replacement, and long-term operational stability depends on maintenance level.

Anhui Tiankang can customize solutions according to working conditions. For example, in steel industry applications with high-humidity flue gas, it adopts anti-condensation filter bags + pre-coating technology to improve bag filter stability; in power industry applications, it optimizes ESP plate layout to handle high-resistivity dust.

2. Cost Comparison

Initial Investment:

ESP typically has higher initial costs than bag filters due to its high-voltage power supply system and large steel structure, but it's more suitable for high-temperature flue gas (above 400°C).

Operation and Maintenance Costs:

Bag replacement (especially in corrosive conditions) is the main expense for industrial electrostatic precipitator filters, while ESP has higher power consumption (especially when needing humidity conditioning for high-resistivity dust).

Anhui Tiankang provides life-cycle cost optimization solutions, such as using membrane-coated filter bags in cement plants to extend service life, or equipping ESP with intelligent high-voltage power supplies to reduce power consumption.

3. Environmental Performance and Adaptability

Emission Standards:

Bag filters can more easily meet ultra-low emission standards (such as <10mg/m³), while ESP performs better in collaborative treatment (such as post desulfurization and denitrification flue gas).

Complex Working Conditions:

ESP has stronger resistance to high temperatures and corrosion, making it suitable for applications like steel sintering machine heads; industrial electrostatic precipitator filters require special filter materials when handling oily mist or sticky dust (such as biomass combustion).

Anhui Tiankang's VOC treatment systems (such as RTO, activated carbon adsorption) can be designed in coordination with dust removal equipment to achieve integrated treatment of multiple pollutants.

Special Dust Treatment in Pharmaceutical Industry: Selection and Maintenance of Explosion-Proof Baghouse Filters

Anhui Tiankang Environmental Technology Co., Ltd., as a leading environmental technology enterprise in China, has rich experience in dust control for the pharmaceutical industry. For the special characteristics of pharmaceutical dust, we provide professional explosion-proof baghouse filter solutions.

1. Characteristics and Challenges of Pharmaceutical Dust

Dust generated during pharmaceutical production typically has the following characteristics:

- Flammable and explosive: Active Pharmaceutical Ingredients (API) dust has low explosion limits (LEL)

- Strong adhesion: Some drug components easily adhere to filter surfaces

- High hygiene requirements: Must comply with GMP cleanliness standards

- Corrosiveness: Some chemical raw materials may be corrosive

2. Key Points for Selecting Explosion-Proof Baghouse Filters

Anhui Tiankang Environmental Technology Co., Ltd. provides customized selection solutions according to different pharmaceutical processes:

| Selection Factor | Solution | Technical Advantage |

|---|---|---|

| Explosion-proof design | Equipped with rupture discs, isolation valves, anti-static filter bags | Complies with ATEX explosion-proof standards |

| Filter material selection | PTFE membrane filter bags, anti-static filter materials | Anti-adhesion, easy cleaning |

| Structural design | Fully enclosed structure, quick-opening access doors | Easy cleaning and maintenance |

| Cleaning system | Pulse jet cleaning + anti-static design | Prevents static accumulation |

3. Key Maintenance Points

- Regular inspection:

- Monthly inspection of anti-static grounding devices

- Quarterly testing of rupture disc sensitivity

- Filter bag replacement cycle:

- Normal conditions: 2-3 years

- High humidity/corrosive conditions: 1-1.5 years

- Cleaning and disinfection:

- CIP online cleaning system

- Regular disinfection treatment

Anhui Tiankang Environmental Technology Co., Ltd. provides: - Customized maintenance plans - Remote monitoring systems - Emergency repair services

4. Success Case

Our solution for a well-known pharmaceutical company: - Air volume: 25,000m³/h - Filtration area: 500m² - Anti-static PTFE membrane filter bags - Equipped with rupture discs + spark detection system - Emission concentration: <5mg/m³

5. Our Advantages

- Rich experience: Serving multiple GMP-certified pharmaceutical companies

- Customization capability: Providing personalized designs based on process characteristics

- Full-cycle service: One-stop service from design, installation to operation

- Technical R&D: Continuous optimization of explosion-proof dust collection technology

Anhui Tiankang Environmental Technology Co., Ltd. is committed to providing pharmaceutical companies with safe, efficient and compliant dust control solutions to help achieve clean production. Please contact our technical team for more professional advice.

Company branches: - Wuxi Company: Wuxi Mingtian Environmental Protection Equipment Co., Ltd. - Anhui Company: Anhui Tiankang Environmental Technology Co., Ltd.

English

English Français

Français عربى

عربى 简体中文

简体中文