-

Top 5 Common Problems with Dust Control Systems and How to Fix Them

Dust control systems are integral to maintaining clean air and preventing pollution in various industrial sectors. A well-designed dust control system is essential for minimizing h...

-

Bag Filters vs. Cartridge Filters: Which is Better for Your System?

Introduction In industries where air pollution control and waste gas treatment are crucial, selecting the right type of dust filter is essential for both operational efficiency and...

-

The Role of Bag Filters in Preventing Air Pollution: Key Benefits and Applications

Introduction Air pollution remains a significant global concern, especially in industrial environments where the emissions of particulate matter, harmful gases, and toxins are freq...

-

A Step-by-Step Guide to Maintaining Your Electrostatic Precipitator

An electrostatic precipitator (ESP) is a crucial component in industrial processes that need to control particulate pollution, particularly in power plants, cement factories, and o...

Anhui Tiankang Environmental Technology Co., Ltd. (formerly Wuxi Mingtian Environmental Protection Equipment Co., Ltd.) was established in 2002. It is a private high-tech enterprise dedicated to environmental protection and governance. The company is mainly engaged in environmental engineering design, environmental protection facility operation and environmental pollution control technology research and development, and undertakes various dust removal systems, flue gas desulfurization and denitrification systems and VOC systems and other engineering general contracting business. We are Customized Spare parts Factory and China cat_name Contractor, At present, the company's products include various bag dust collector systems (including raw materials, batching, pelletizing, sintering, ironmaking, steelmaking, rolling and other aspects of steel mills; foundry industry, pharmaceutical industry, glass industry, cement industry, non-ferrous metal smelting industry, etc.), converter primary dust removal flue gas recovery system, slag treatment system, VOC treatment system (including activated carbon adsorption device, catalytic combustion device, RTO and UV pretreatment + zeolite wheel adsorption + RCO device, etc.), as well as flue gas heat exchanger, cooler, capture hood (including electric furnace fully enclosed hood, roof hood, converter front and rear hood, blast furnace tapping port, slag skimmer hood, various belt hoods, and various scattered point hoods in steelmaking workshop, etc.), mobile ventilation slots, mufflers, desulfurization towers, ash conveying equipment, ventilation duct flexible compensators, pipeline sliding supports, condensate drainers, bags, keels and other customized accessories.

Tiankang Environment has two branches. One is Wuxi Mingtian Environmental Protection Equipment Co., Ltd., which is located in Wuxi, a famous city in the south of the Yangtze River with a developed economy and picturesque scenery. It has convenient transportation and rich natural and cultural landscapes. The other is Anhui Tiankang Environmental Technology Co., Ltd. (formerly Anhui Mingtian Energy Saving and Environmental Protection Engineering Co., Ltd.), which is located in Lu'an, an old revolutionary base with a long history, mountains and water, and a pleasant climate. The company sincerely welcomes friends from all walks of life to visit and guide with an open attitude. It is willing to provide technical services for all walks of life and provide a stage for people with lofty ideals to display their wisdom and talents.

The company focuses on the future, is determined to protect the environment, and regards returning a fresh, blue and clear sky to mankind as the company's goal!

How effective are dust collection hoods in capturing fine particulate matter?

Selecting a reliable spare parts contractor for dust collector systems is critical to maintaining operational efficiency, reducing downtime, and ensuring compliance with environmental regulations. Dust collectors are essential in industries such as steel manufacturing, cement production, pharmaceuticals, and metal smelting, where effective particulate control is necessary. A high-quality spare parts supplier must offer not only durable components but also technical expertise, reliable sourcing, and comprehensive after-sales support.

1. Technical Expertise and Industry Experience

A reputable spare parts contractor should possess deep technical knowledge of dust collection systems, including bag filters, flue gas treatment, VOC control, and auxiliary components such as hoods, mufflers, and ash conveyors. Experience in serving industries like steelmaking, cement, and pharmaceuticals is crucial, as each sector has unique dust control challenges.

Contractors with a strong engineering background can provide tailored solutions, ensuring compatibility between spare parts and existing systems. Look for a supplier with a proven track record in environmental engineering, system design, and pollution control technology. Companies that engage in research and development (R&D) often offer innovative, high-performance components that improve filtration efficiency and reduce maintenance costs.

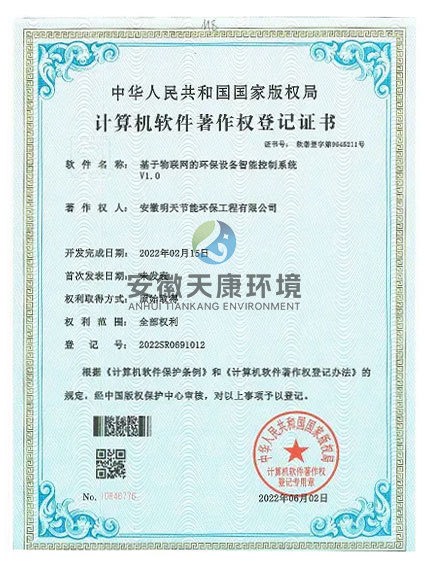

2. Product Quality and Certification Compliance

The quality of spare parts directly impacts dust collector performance. A dependable spare parts supplier should provide components manufactured to international standards, such as ISO certifications, and hold industry-specific licenses. High-grade materials, precision engineering, and rigorous quality control processes are essential for durability.

Key dust collector components—such as filter bags, cages (keels), flexible compensators, and hoods—must withstand harsh operating conditions, including high temperatures, abrasive dust, and corrosive gases. A contractor with patented technologies and a full-chain quality assurance system ensures that parts meet exact specifications. Additionally, documentation such as material test reports and compliance certificates should be available upon request.

3. Availability of OEM and Customized Parts

Many dust collector systems require specialized or hard-to-find components. A reliable spare parts contractor should offer both OEM (Original Equipment Manufacturer) and custom-engineered parts to fit various system configurations. This includes bespoke solutions for unique applications, such as converter primary dust removal systems, steel slag handling, or VOC treatment setups.

Suppliers with in-house manufacturing capabilities can produce tailored components like duct supports, condensate drainers, or sliding pipe supports, reducing lead times and ensuring precise compatibility. The ability to source obsolete or discontinued parts is another advantage, minimizing downtime for older systems.

4. Comprehensive After-Sales Support

A trustworthy spare parts supplier does not merely sell components but also provides technical guidance, installation support, and maintenance services. Post-purchase assistance is crucial for troubleshooting, optimizing system performance, and ensuring proper part integration.

Some contractors offer inventory management services, helping customers maintain critical spare parts stock to prevent unexpected breakdowns. Others provide emergency dispatch for urgent replacements, ensuring minimal disruption to operations. A strong after-sales framework enhances long-term reliability and operational efficiency.

5. Supply Chain and Logistics Reliability

Timely delivery is critical in industrial operations where downtime leads to significant financial losses. A dependable spare parts contractor should have a robust supply chain network, ensuring consistent availability of high-demand components. International shipping capabilities are beneficial for multinational operations.

Transparent logistics tracking, flexible procurement options (such as bulk purchasing discounts), and efficient order processing contribute to a seamless supply experience. Contractors with well-established warehousing and distribution systems can reduce lead times, ensuring parts arrive when needed.

6. Reputation and Customer References

A contractor’s reputation in the industry is a strong indicator of reliability. Customer testimonials, case studies, and long-term partnerships with major industrial players demonstrate credibility. Requesting references from past clients in similar industries can provide insights into product performance and service quality.

Third-party certifications, industry awards, and participation in environmental technology forums further validate a supplier’s expertise. A spare parts contractor with a history of successful turnkey projects in dust removal and flue gas treatment is more likely to deliver high-quality components and support.

Choosing the right dust collector spare parts contractor requires careful evaluation of technical expertise, product quality, customization capabilities, after-sales support, logistics efficiency, and industry reputation. A supplier with strong engineering credentials, certified manufacturing processes, and a commitment to innovation will ensure optimal dust collection system performance.

By prioritizing these factors, businesses can secure a long-term partnership with a spare parts supplier that enhances operational reliability, reduces maintenance costs, and supports compliance with environmental regulations. Investing in high-quality components from a trusted contractor ultimately leads to sustainable and efficient dust control solutions.

Key Considerations When Selecting a Spare Parts Contractor (Summary Table)

| Factor | Key Aspects to Evaluate |

|---|---|

| Technical Expertise | Industry experience, R&D capabilities, engineering support |

| Product Quality | ISO certifications, material durability, compliance documentation |

| Customization | OEM and bespoke parts, obsolete component sourcing |

| After-Sales Support | Maintenance services, emergency response, inventory management |

| Logistics Efficiency | Lead times, international shipping, supply chain stability |

| Reputation | Customer references, industry awards, case studies |

This structured approach ensures businesses select a spare parts contractor capable of meeting their dust collector maintenance and performance needs effectively.

English

English Français

Français عربى

عربى 简体中文

简体中文