Low-Pressure Pulse Jet Bag Dust Collector

CONTACT US-

Top 5 Common Problems with Dust Control Systems and How to Fix Them

Dust control systems are integral to maintaining clean air and preventing pollution in various industrial sectors. A well-designed dust control system is essential for minimizing hazardous airborne particles, ensuring compliance with environmental regulations, and improving workp...

-

Bag Filters vs. Cartridge Filters: Which is Better for Your System?

Introduction In industries where air pollution control and waste gas treatment are crucial, selecting the right type of dust filter is essential for both operational efficiency and environmental responsibility. Among the various filtration systems, bag filters and cartridge filte...

-

The Role of Bag Filters in Preventing Air Pollution: Key Benefits and Applications

Introduction Air pollution remains a significant global concern, especially in industrial environments where the emissions of particulate matter, harmful gases, and toxins are frequent. Effective air pollution control systems are crucial to ensuring that industries comply with en...

Low-Pressure Pulse Jet Bag Dust Collector: Is it the future of efficient dust collection?

In an increasingly industrialized environment, efficient dust collection systems are becoming a pressing need across industries. Low-Pressure Pulse Jet Bag Dust Collectors (LPPJBs) are excelling in many industries due to their high dust removal efficiency and low energy consumption. With increasingly stringent environmental regulations and the growing popularity of sustainable development, understanding the advantages and prospects of low-pressure pulse jet bag dust collectors is particularly important.

What is a Low-Pressure Pulse Jet Bag Dust Collector?

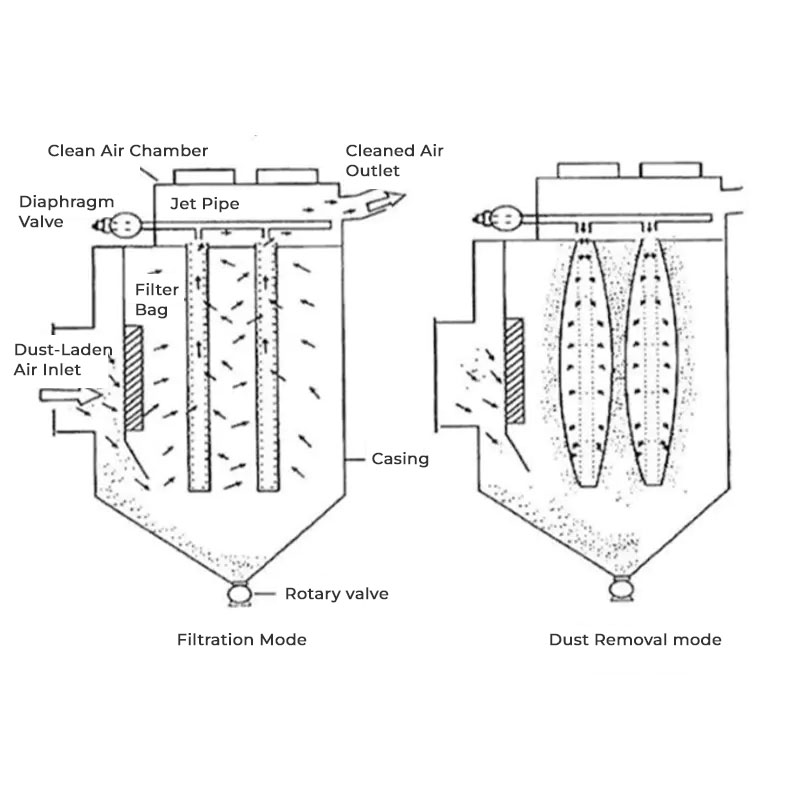

A low-pressure pulse jet bag dust collector is a type of dust collection device that captures and filters particulate matter from industrial exhaust gases through a series of fabric filter bags. Unlike traditional mechanical filters, the pulse jet design periodically injects low-pressure compressed air into the filter bags, helping to remove accumulated dust, prevent clogging, and maintain high dust collection efficiency over time.

In this system, dust-laden air first passes through filter bags, where dust particles are captured. The purified air is then released into the atmosphere. The pulse jet mechanism ensures clean and efficient filter bags, eliminating the need for frequent manual cleaning or replacement.

Key Advantages of the Low-Pressure Pulse Jet Bag Dust Collector

1. Energy Efficiency: The low-pressure pulse jet mechanism is more energy-efficient than high-pressure systems, reducing energy consumption, thereby lowering operating costs and helping to reduce the carbon footprint.

2. Continuous Operation: The system automatically cleans itself, minimizing downtime and ensuring consistent, stable operation, thereby increasing productivity.

3. Higher Dust Removal Efficiency: The pulse jet action helps the system handle finer, stickier particles, ensuring efficient dust removal over the long term and meeting stringent air quality standards.

4. Extended Filter Bag Life: Because the pulse jet system cleans the filter bags more gently, the filter bags last longer, requiring less frequent replacement, further reducing operating costs.

5. Compact Design: Low-Pressure Pulse Jet Bag Dust Collectors are relatively small, making them suitable for industrial environments with limited space.

How a Low-Pressure Pulse Jet Bag Dust Collector Works

When a low-pressure pulse jet bag dust collector begins operation, dust-laden air enters the device. As the air passes through the filter bags, dust is captured by the bags, and the purified air is discharged from the device. Periodically, the system injects a burst of low-pressure compressed air into each bag, causing it to expand and vibrate, effectively cleaning the bag.

This low-pressure design of the pulse jet system ensures long-term filter bag life while significantly reducing energy consumption. As dust is shaken off, it falls into the dust hopper for easy disposal. This ensures stable operation over extended periods of time, without compromising efficiency due to filter bag clogging.

Applications of Low-Pressure Pulse Jet Bag Dust Collectors

Low-pressure pulse jet bag dust collectors are widely used in industries requiring efficient dust removal. Key applications include:

1. Cement and mining industries: These industries generate large amounts of dust and particulate matter, which are harmful to workers and the environment. LPJBDC systems effectively remove this dust, improving workplace air quality.

2. Pharmaceutical and food processing industries: These industries have high requirements for environmental hygiene. LPJBDC filters out very fine particles, ensuring clean and safe production processes.

3. Steel and metallurgy industries: In the steel and metallurgy industries, cutting, grinding, and welding processes generate large amounts of dust, making LPJBDC systems ideal for these applications.

4. Power generation industry: Fossil fuel-fired power plants generate large amounts of dust and other particulate matter. LPJBDC systems help reduce particulate emissions and ensure compliance with environmental regulations.

5. Woodworking and textile industries: These industries generate large amounts of dust, which, if not controlled, can pose a fire risk. The LPJBDC system effectively removes these dusts and ensures environmental safety.

Why choose Anhui Tiankang Environmental Technology Co., Ltd.?

Since its establishment in 2002, Anhui Tiankang Environmental Technology Co., Ltd. has been committed to providing efficient environmental protection solutions for various industries. As a leading manufacturer of low-pressure pulse jet bag dust collectors, Anhui Tiankang Environmental Technology Co., Ltd. has extensive design and R&D experience, enabling us to provide customized dust removal systems for a wide range of industrial needs.

Leveraging its extensive expertise in environmental protection equipment, Anhui Tiankang Environmental Technology Co., Ltd. not only provides highly efficient low-pressure pulse jet bag dust collectors but also optimizes and customizes systems to meet specific customer needs. As a renowned domestic manufacturer of environmental protection equipment, Anhui Tiankang Environmental Technology Co., Ltd. continuously develops new technologies, striving to provide more energy-efficient and environmentally friendly dust removal solutions for various industries.

With the increasing global focus on sustainable development and environmental protection, the demand for dust removal technology is increasing. Low-pressure pulse jet baghouses represent the future of industrial dust collection, combining advanced technology with energy-saving features to reduce energy consumption while increasing the system's dust collection efficiency.

English

English Français

Français عربى

عربى 简体中文

简体中文