Negative Pressure Back-Blowing Bag Dust Collector

CONTACT US-

Top 5 Common Problems with Dust Control Systems and How to Fix Them

Dust control systems are integral to maintaining clean air and preventing pollution in various industrial sectors. A well-designed dust control system is essential for minimizing hazardous airborne particles, ensuring compliance with environmental regulations, and improving workp...

-

Bag Filters vs. Cartridge Filters: Which is Better for Your System?

Introduction In industries where air pollution control and waste gas treatment are crucial, selecting the right type of dust filter is essential for both operational efficiency and environmental responsibility. Among the various filtration systems, bag filters and cartridge filte...

-

The Role of Bag Filters in Preventing Air Pollution: Key Benefits and Applications

Introduction Air pollution remains a significant global concern, especially in industrial environments where the emissions of particulate matter, harmful gases, and toxins are frequent. Effective air pollution control systems are crucial to ensuring that industries comply with en...

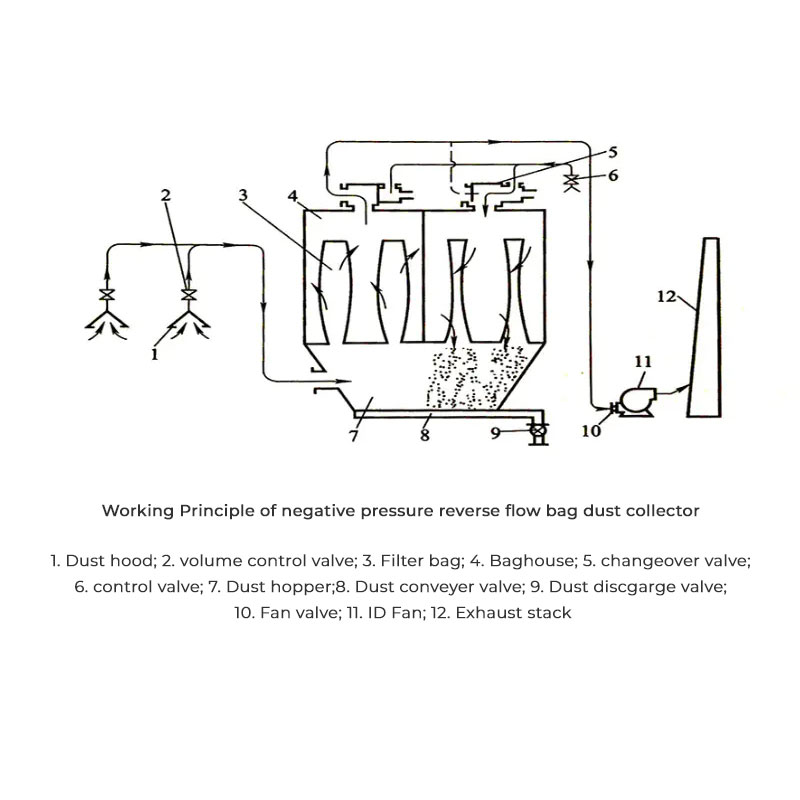

How has the Negative Pressure Back-Blowing Bag Dust Collector become a new favorite in future environmental protection technology?

With the continuous acceleration of industrialization, environmental pollution is becoming increasingly serious, especially dust emissions from industrial production, which have a more pronounced impact on air quality. To address this challenge, the Negative Pressure Back-Blowing Bag Dust Collector has gradually become a key piece of equipment in the industrial dust removal field. As a highly efficient dust removal technology, it not only effectively removes dust from the air but also reduces energy consumption and improves the company's environmental performance. So, why are negative pressure back-blowing bag dust collectors so popular? How will they lead the future development of the environmental protection industry?

The Negative Pressure Back-Blowing Bag Dust Collector is a dust removal device widely used in industrial production. It operates by using negative pressure to back-blow air to remove dust accumulated on the filter bags. The main components of this device include a dust collection box, filter bags, a negative pressure blower, and a back-blowing device. Compared with traditional dust collectors, negative pressure back-blowing bag dust collectors offer higher dust removal efficiency and lower operating costs, making them increasingly popular among companies.

Advantages of Negative Pressure Back-Blowing Bag Dust Collectors

1. Highly Efficient Dust Removal

Negative pressure back-blowing bag dust collectors operate at high air volumes and negative pressures, effectively improving dust removal efficiency. They precisely filter minute dust particles, ensuring that exhaust gases meet environmental standards and minimizing the impact of dust pollution on the environment.

2. Energy Saving and Environmental Protection

The negative pressure design of this equipment significantly reduces energy consumption during the dust removal process, thereby reducing energy consumption in the production process. Furthermore, the back-blowing mechanism effectively removes dust accumulated on the filter bags, reducing the need for frequent bag replacements and further improving economic efficiency.

3. High Degree of Automation

Negative pressure back-blowing bag dust collectors are generally equipped with an automatic control system that monitors operating status in real time and adjusts air volume and back-blowing frequency based on actual conditions. This highly automated design not only improves operational stability but also reduces manual intervention and operational risks.

4. Easy Maintenance

Compared to traditional dust removal equipment, negative pressure back-blowing bag dust collectors are much easier to maintain. Its filter bags can be easily removed and cleaned, resulting in a low equipment failure rate and reduced maintenance costs for businesses.

Application Prospects of Negative Pressure Back-Blowing Bag Dust Collectors

Negative pressure back-blowing bag dust collectors are widely used for dust control in industries such as steel, building materials, chemicals, mining, power generation, and metallurgy. With increasingly stringent environmental regulations, especially in my country's context of promoting green development, market demand for negative pressure back-blowing bag dust collectors is expected to continue to grow.

1. Driven by Environmental Protection Policies

With the implementation of policies such as the "Action Plan for Air Pollution Prevention and Control" and the "Industrial Pollution Source Emission Standards," businesses are facing more stringent environmental protection requirements. Negative pressure back-blowing bag dust collectors, with their high efficiency and low energy consumption, are an ideal choice for meeting these requirements.

2. Popularization of Green Development Concepts

With the global adoption of green development concepts, the application scope of environmental protection equipment will further expand. As a representative example of green environmental protection equipment, negative pressure back-blowing bag dust collectors will occupy an increasingly important position in the global environmental protection market.

Anhui Tiankang Environmental Technology Co., Ltd.: Driving Industry Development

Anhui Tiankang Environmental Technology Co., Ltd. is a high-tech enterprise specializing in environmental protection and pollution control. The company primarily engages in environmental engineering design, environmental facility operation, and pollution control technology research and development. It undertakes general contracting for various types of dust removal systems, flue gas desulfurization and denitrification systems, and VOCs systems. As a leading domestic manufacturer of negative pressure back-blowing bag dust collectors, Anhui Tiankang Environmental Technology Co., Ltd. leverages its superior technical advantages and strong R&D capabilities to continuously promote innovation and application of environmental protection technologies.

Through years of technological accumulation and market experience, Anhui Tiankang Environmental Technology Co., Ltd. has achieved significant success in the field of negative pressure back-blowing bag dust collectors. The company is committed to providing customized dust removal solutions for various industrial enterprises, helping them reduce production costs and improve environmental efficiency.

With increasing environmental awareness and policy support, the application of negative pressure back-blowing bag dust collectors will become increasingly widespread. From improving industrial production efficiency to promoting green development, this technology is undoubtedly a shining star in the future of environmental protection.

English

English Français

Français عربى

عربى 简体中文

简体中文