-

Top 5 Common Problems with Dust Control Systems and How to Fix Them

Dust control systems are integral to maintaining clean air and preventing pollution in various industrial sectors. A well-designed dust control system is essential for minimizing h...

-

Bag Filters vs. Cartridge Filters: Which is Better for Your System?

Introduction In industries where air pollution control and waste gas treatment are crucial, selecting the right type of dust filter is essential for both operational efficiency and...

-

The Role of Bag Filters in Preventing Air Pollution: Key Benefits and Applications

Introduction Air pollution remains a significant global concern, especially in industrial environments where the emissions of particulate matter, harmful gases, and toxins are freq...

-

A Step-by-Step Guide to Maintaining Your Electrostatic Precipitator

An electrostatic precipitator (ESP) is a crucial component in industrial processes that need to control particulate pollution, particularly in power plants, cement factories, and o...

Bag Filter Dust Collector Contractor

The bag filter uses bags as filtering equipment to separate the particulate matter in the dusty flue gas from the gas, thereby achieving the purpose of the dust collector. It is suitable for dry dust removal devices and is suitable for capturing fine, dry non-fibrous dust. The filter bag is made of textile filter cloth or non-textile felt, and uses the filtering effect of fiber fabric to filter the dusty gas. When the dusty gas enters the bag filter, the dust with large particles and high specific gravity settles down due to gravity and falls into the ash hopper. When the gas containing finer dust passes through the filter material, the dust is retained, so that the gas is purified, and the dust attached to the surface of the bag is blown into the ash bin regularly, and the dust is recycled as a raw material for secondary use.

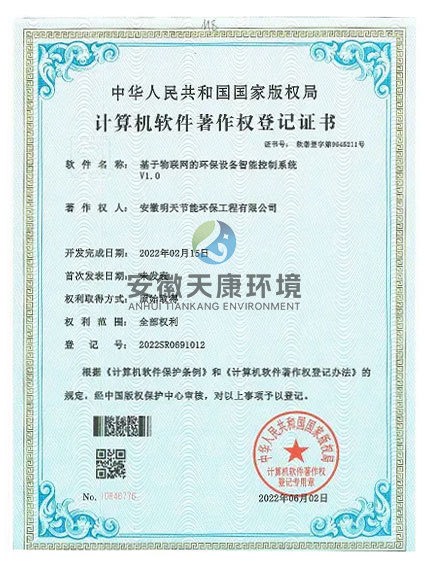

Anhui Tiankang Environmental Technology Co., Ltd. (formerly Wuxi Mingtian Environmental Protection Equipment Co., Ltd.) was established in 2002. It is a private high-tech enterprise dedicated to environmental protection and governance. The company is mainly engaged in environmental engineering design, environmental protection facility operation and environmental pollution control technology research and development, and undertakes various dust removal systems, flue gas desulfurization and denitrification systems and VOC systems and other engineering general contracting business. We are Customized Bag Filter Dust Collector Factory and China Bag Filter Dust Collector Contractor, At present, the company's products include various bag dust collector systems (including raw materials, batching, pelletizing, sintering, ironmaking, steelmaking, rolling and other aspects of steel mills; foundry industry, pharmaceutical industry, glass industry, cement industry, non-ferrous metal smelting industry, etc.), converter primary dust removal flue gas recovery system, slag treatment system, VOC treatment system (including activated carbon adsorption device, catalytic combustion device, RTO and UV pretreatment + zeolite wheel adsorption + RCO device, etc.), as well as flue gas heat exchanger, cooler, capture hood (including electric furnace fully enclosed hood, roof hood, converter front and rear hood, blast furnace tapping port, slag skimmer hood, various belt hoods, and various scattered point hoods in steelmaking workshop, etc.), mobile ventilation slots, mufflers, desulfurization towers, ash conveying equipment, ventilation duct flexible compensators, pipeline sliding supports, condensate drainers, bags, keels and other customized accessories.

Tiankang Environment has two branches. One is Wuxi Mingtian Environmental Protection Equipment Co., Ltd., which is located in Wuxi, a famous city in the south of the Yangtze River with a developed economy and picturesque scenery. It has convenient transportation and rich natural and cultural landscapes. The other is Anhui Tiankang Environmental Technology Co., Ltd. (formerly Anhui Mingtian Energy Saving and Environmental Protection Engineering Co., Ltd.), which is located in Lu'an, an old revolutionary base with a long history, mountains and water, and a pleasant climate. The company sincerely welcomes friends from all walks of life to visit and guide with an open attitude. It is willing to provide technical services for all walks of life and provide a stage for people with lofty ideals to display their wisdom and talents.

The company focuses on the future, is determined to protect the environment, and regards returning a fresh, blue and clear sky to mankind as the company's goal!

How to Choose the Filter Bag Material for Bag Filter Dust Collectors? – Professional Advice from Anhui Tiankang Environmental Technology Co., Ltd.

The core component of a bag filter dust collector is the filter bag, and its material directly affects filtration efficiency, operating costs, and equipment lifespan. As a high-tech enterprise specializing in environmental protection and pollution control, Anhui Tiankang Environmental Technology Co., Ltd. has extensive experience in designing bag filter systems for industries such as steel, cement, pharmaceuticals, and glass. Below, we analyze key considerations for selecting filter bag materials based on industrial application requirements:

1. Selecting Filter Media Based on Dust Characteristics

- High-temperature dust (e.g., steel, cement industries): High-temperature resistant materials such as P84 (polyimide), PTFE (polytetrafluoroethylene), or glass fiber membrane-coated filter media are required, capable of withstanding temperatures above 200°C for extended periods.

- Corrosive gases (e.g., chemical, pharmaceutical industries): PTFE filter bags or FMS (Fluorine-Modified Composite) filter media are recommended due to their strong resistance to acid and alkali corrosion.

- Sticky dust (e.g., asphalt, tar): Anti-stick coated filter media or PTFE membrane-coated filter bags should be used to prevent clogging.

2. Matching Filter Material with Cleaning Method

- Pulse-jet cleaning: Suitable for high-strength polyester (PE) or Nomex filter bags, which offer excellent mechanical wear resistance.

- Reverse-air cleaning: Glass fiber filter bags or PPS (polyphenylene sulfide) are recommended due to their flexible structure, which accommodates low-frequency cleaning.

3. Balancing Cost and Lifespan

- Low-cost applications: For standard working conditions, polyester (PE) filter bags can be used—they are inexpensive but have a shorter lifespan (1-2 years).

- Longevity requirements: High-value industries (e.g., pharmaceuticals, food) should opt for PTFE membrane-coated filter bags. Although the initial cost is higher, their service life can exceed 5 years.

4. Customized Solutions from Anhui Tiankang

With extensive experience in steel plants (sintering, steelmaking), cement plants, and non-ferrous metal smelting, Anhui Tiankang provides:

- Filter material testing services: Analyzes dust samples to recommend the optimal filter media combination.

- Membrane coating technology: Uses PTFE coating to enhance filtration precision (emission concentration <10mg/m³).

- Full lifecycle support: Offers one-stop technical services from selection and installation to maintenance.

Optimizing Industrial Air Quality: Anhui Tiankang's Expertise in Bag Filter Dust Collection Systems

As a leading environmental technology provider since 2002, Anhui Tiankang Environmental Technology Co., Ltd. has established itself as a trusted partner for industrial air pollution control across multiple sectors. Our specialized bag filter dust collectors represent cutting-edge solutions for particulate matter control in challenging industrial environments.

Comprehensive Dust Collection Solutions for Diverse Industries

With extensive project experience spanning steel production, cement manufacturing, pharmaceutical processing and beyond, we understand the unique dust control requirements of each sector:

- Steel Industry Applications: Our systems effectively handle dust from sintering, ironmaking, steelmaking and rolling operations, with specially designed capture hoods for electric furnaces, converters and tapping stations.

- Cement Production: Customized solutions for raw material handling, kiln feed and finish grinding processes, ensuring compliance with strict emission standards.

- Specialized Industrial Solutions: From foundry operations to non-ferrous metal smelting, our bag filters are engineered for specific process conditions.

Advanced Technology for Superior Performance

Our bag filter systems incorporate several innovative features:

- High-Efficiency Filtration Media: Utilizing premium materials including PTFE, Nomex and P84 for optimal performance in various temperature and chemical conditions.

- Intelligent Cleaning Systems: Automated pulse-jet cleaning mechanisms that maintain optimal pressure drop while minimizing compressed air consumption.

- Integrated Emission Control: Combined systems incorporating bag filters with our VOC treatment technologies (RTO, RCO) for comprehensive air pollution control.

Engineering Excellence and Custom Design Capabilities

What sets Anhui Tiankang apart is our complete engineering approach:

- Process-Specific Designs: Each system is customized based on detailed analysis of dust characteristics, gas volumes and operational parameters.

- Ancillary Equipment Integration: Our solutions include complementary components like flue gas heat exchangers, coolers and specialized ductwork.

- Turnkey Project Execution: From initial assessment to commissioning, we manage all aspects of dust collection system implementation.

Commitment to Environmental Sustainability

Aligned with our vision of "returning a fresh, blue and clear sky to mankind," our bag filter systems deliver:

- Consistent compliance with increasingly stringent environmental regulations

- Energy-efficient operation through optimized system design

- Long service life with our premium-quality components and materials

- Comprehensive after-sales support and maintenance services

With facilities in Wuxi and Lu'an, Anhui Tiankang Environmental Technology Co., Ltd. stands ready to assist industries across China and beyond in achieving their air quality goals. Our team of experienced engineers provides technical consultation and customized solutions for even the most challenging dust collection applications.

English

English Français

Français عربى

عربى 简体中文

简体中文